This checklist helps employers and employees in general industry and construction comply with the Occupational Safety and Health Administration (OSHA)’s standards for welding, cutting, and brazing. It is based on 29 Code of Federal Regulations (CFR) Part 1910, Subpart Q, and 29 CFR Part 1926, Subpart J, OSHA Standards for the General and Construction Industry.

These standards can be found on OSHA’s website at www.osha.gov.Employers in the construction industry should review the section dealing with general industry, because some of the questions apply to all worksites. Compliance with this checklist does not necessarily assure full compliance with all OSHA standards.

Read the welding and cutting and brazing Checklist by Flipping the checklist file below :

Frequently Cited Welding Standards in General Industry

1910.253(b)(4)(i)

Oxygen cylinders shall not be stored near highly combustible material (especially oil and grease); near reserve stocks of carbide, acetylene, or other fuel gas cylinders; near any other substance likely to cause or accelerate fire; or in an acetylene generator compartment.

1910.253(b)(4)(iii)

Oxygen cylinders in storage shall be separated from fuel-gas cylinders or combustible materials (especially oil or grease) a minimum of 20 feet or by a noncombustible barrier at least five (5) feet high having a fire-resistance rating of at least one-half hour.

1910.253(b)(2)(ii)

Inside buildings, cylinders shall be stored in a well-protected, well-ventilated, dry location at least 20 feet from highly combustible materials such as oil or excelsior. Cylinders should be stored in definitely assigned places away from elevators, stairs, or gangways. Assigned storage spaces shall be located where cylinders will not be knocked over or damaged by passing or falling objects, or subject to tampering by unauthorized persons. Cylinders shall not be kept in unventilated enclosures such as lockers or cupboards. ( Read: Hot Work Controls and its Permit to work Form )

1910.253(b)(2)(iii)

Empty cylinders shall have their valves closed.

1910.253(b)(2)(iv)

Valve protection caps, where cylinders are designed to accept a cap, shall always be in place, hand-tight, except where cylinders are in use or connected for use.

1910.254(d)(9)(iii)

Cables with damaged insulation or exposed bare conductors shall be replaced. Joining lengths of work and electrode cables shall be done by the use of connecting means specifically intended for the purpose. The connecting means shall have insulation adequate for the service conditions

The content of the welding and cutting and brazing Checklist

- Frequently Cited Standards in General Industry

- Welding, Cutting, and Brazing Checklist – General Industry

- Table 1: Ventilation Requirements – General Industry

- Frequently Cited Standards in the Construction Industry

- Welding, Cutting, and Brazing Checklist – Construction

- Table 2: Ventilation Requirements – Construction

Also, Read HIRA, HSE Hazards & Effects Management Process (HEMP) & Risk Register Template

Download The Forms

Welding and cutting and Brazing Checklist

More Downloads

- Welding, Cutting, and Brazing Checklist

- Construction Safety Inspection Checklist

- Permit To work Forms

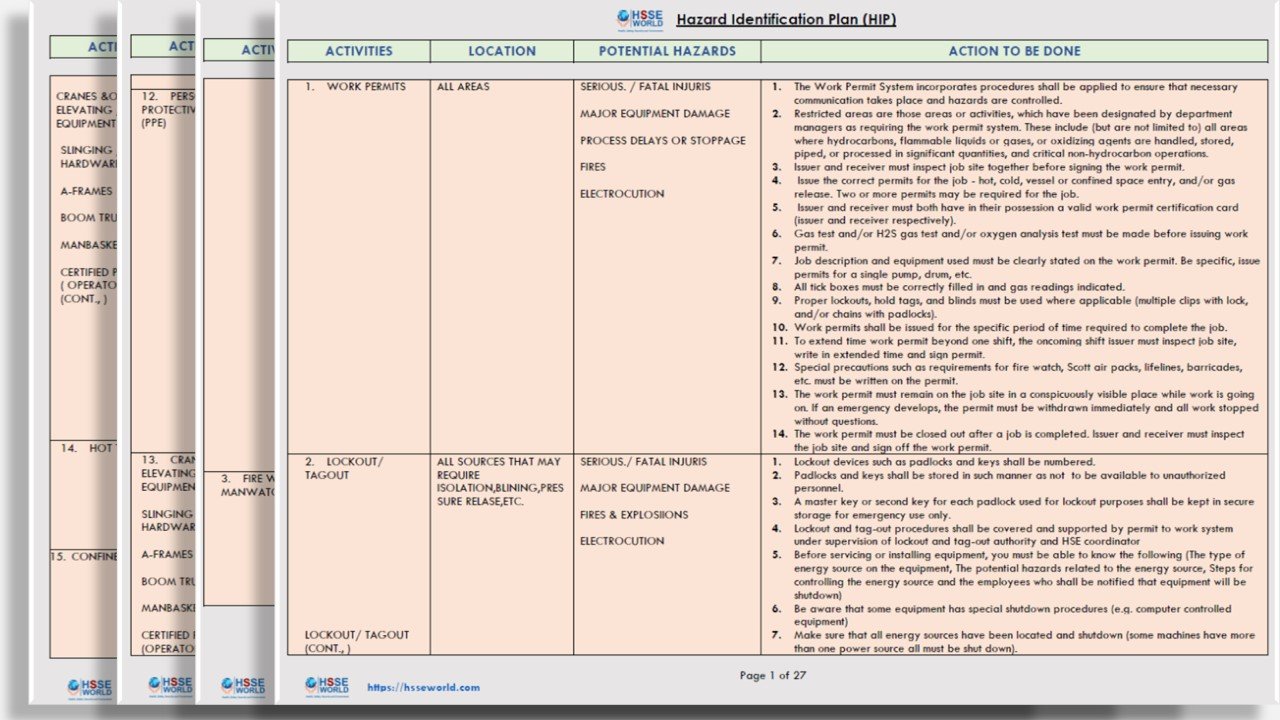

- Hazard Identification Plan (HIP) Template

- Pre-Startup Safety Review Checklist (PSSR)

- 35 Inspection forms for Rig Check

- Chemical Risk Assessment form

- 22-Safety Inspection Checklists

- Safety Task Assessment Form

- Suspended Scaffold Pre-Operation Inspection Checklist

- Grating-Decking-Floor- handrail-Removal Form

- Electrical Inspection Checklists

- Annual Internal Audit Form

- Mobile Scaffold Inspection checklist

- Simultaneous Operation (SIMOPS) checklist

- Temporary Construction Facilities (TCF) Inspection checklist

- HIRA, HSE Hazards & Effects Management Process (HEMP) & Risk Register Template

- Ladder Inspection Form

- Construction safety Inspection checklist

- Equipment Safe Operating Procedures- SOP 61 checklist

- Permit to Work (PTW ) AUDIT CHECKLIST

- Hygiene and Sanitation Inspection Checklist

- Electric Arc Welding and Cutting Checklist

- Pressure Testing Checklist

- Crane Suspended Personnel Platform (MANBASKET) Permit

- Laboratory Inspection Checklist Form

- CRANE INSPECTION REPORT

- Scaffold Register and Inspection Checklist

- Portable Ladder Self Inspection checklist

- Process Safety Management (PSM) Compliance checklist

- OSHA Inspection Checklist 8-Pages

- Job Hazard Analysis form

- Incident Report Form

- Safety Inspection Form

- Contractor Weekly HSE Report Form

- Competent Person Designation form

- Compressed Gas Cylinders Access Control Inspection Checklist

- Emergency Drill After Action Review form

- Emergency Drill Table Top meeting Form

- Slips,Trips and Falls checklist

- Lift Plan Form

- Machines Access Control Inspection Checklists

- Camp Inspection form