Temporary Construction Facilities (TCF) Inspection checklist

Site layout planning consists of identifying the facilities needed to support construction operations, determining their size, shape and positioning them within the boundaries of the available on-site or remote areas. Despite the importance of site space as a resource, site-layout planning is often neglected and the attitude of engineers has been that it will be done as the project progresses. Good site layout, however, is important to promote safe and efficient operations, minimize travel time, decrease material handling and avoid obstructing material and equipment movements, especially in the case of large Projects

In addition, such a problem becomes far from trivial if a construction site is confined due to the lack of available space, or if the site is very large, then traveling between facilities can be considerably time-consuming. When temporary site-level facilities are required to be located on a construction site, the locations of buildings to be constructed are assumed to be known. These locations are used to define available sites for temporary facilities. Then the problem can be defined as the allocation of predetermined facilities like warehouses, job offices, workshops, and batch plants so as to optimize an objective subject to layout constraints and requirements. Using such a definition of the problem, the formulation in terms of a combinatorial optimization problem has been attempted. A number of studies were conducted in order to improve site layout planning in construction projects. These studies adopted a wide range of methodologies and development tools including neural networks, simulation, knowledge-based systems, and genetic algorithms

A badly planned and untidy site is the underlying cause of many accidents resulting from falls of material and collisions between workers and plant or equipment. Space constraints, particularly in urban worksites, are nearly always the biggest limiting factor and a layout that caters best for the safety and health of workers may appear to be difficult to reconcile with productivity. Proper planning by management is an essential part of preparation and budgeting for the safe and efficient running of a construction operation.

Before work even begins on-site, thought needs to be given to:

- the sequence or order in which work will be done and to any especially hazardous operations or processes;

- access for workers on and around the site. Routes should be free from obstruction and from exposure to hazards such as falling materials, materials-handling equipment, and vehicles. Suitable warning notices should be posted. Routes to and from welfare facilities need equal consideration. Edge protection will be required at the edge of floor openings and stairs, and wherever there is a drop of 2 m or more

- routes for vehicular traffic. These should be “one way” as far as practicable. Traffic congestion prejudices the safety of workers, especially when impatient drivers unload goods hurriedly;

- storage areas for materials and equipment. Materials need to be stored as close as possible to the appropriate workstation, e.g. sand and gravel close to the cement-batching plant, and timber close to the joinery shop. If this is not practicable, it is important to schedule the arrival of materials;

- the location of construction machinery. This is usually dependent on operational requirements so that tower cranes are subject to constraints such as their radius of operation, and pick-up and unloading points. The objective should be to avoid the need to slew the load over workers;

- the location of trade workshops – these are not usually moved after they are built;

- the location of medical and welfare facilities. On large sites sanitary facilities for both sexes should be provided at several locations;

- artificial lighting at places where work continues or workers pass after dark;

- site security. The site should be fenced in to keep out unauthorized persons, children in particular, and to protect the public from site hazards. The type of fencing will depend on the location of the site, but in populated areas, it should be at least 2 m high and without gaps or holes. Overhead protection will be necessary if tower crane loads pass over public thoroughfares;

- arrangements to keep the site tidy and for the collection and removal of waste;

- the need for low-voltage electric power supplies for temporary lighting, portable tools, and equipment;

- training needs of both workers and supervisors.

- Point to remember

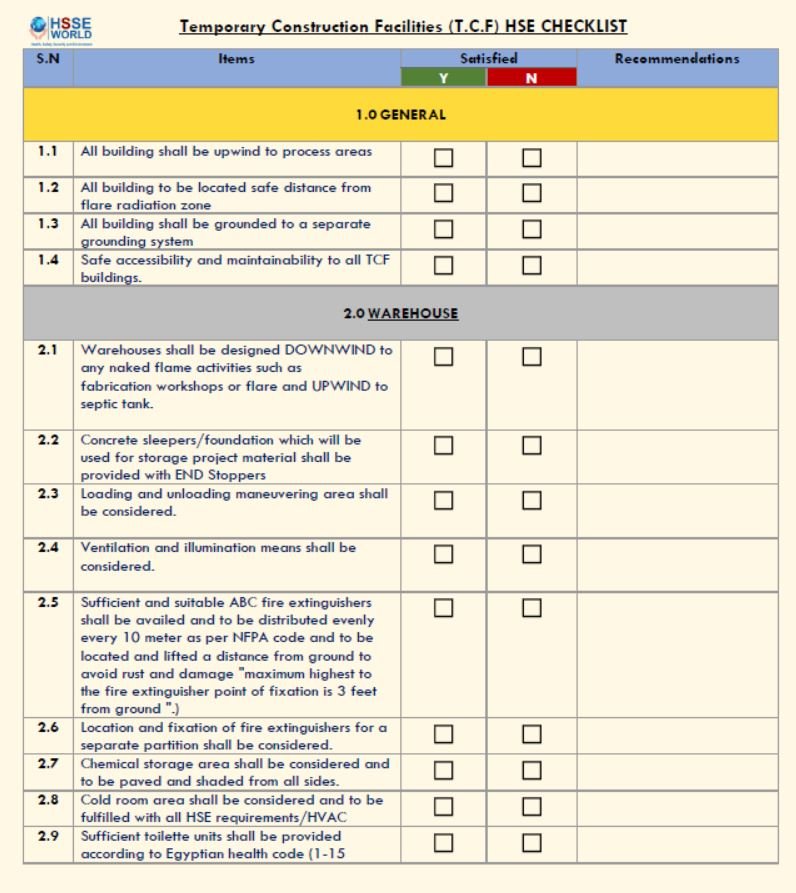

The following checklist the main points to consider when you are checking the safety of your site.

Download The checklist

Temporary construction Facilites( TCF) Safety checkilist could be used as a guideline during Inspection and survey for Temporary facilites at work site the checklist are editable and could be modified to fit your purpose

Download Editable checklist

Download PDF Checklist