Firefighting Precautions at Facilities with Combustible Dust the primary purpose is to protect emergency responders from harm by giving them a framework for gathering the necessary information prior to an emergency and converting it into safe operating procedures. In this document, emergency responders include firefighters, fire brigade members, hazardous materials teams, and others who might be called upon to respond when a fire or explosion occurs.

This document is not intended to provide specific strategies or tactics to be used during emergency responses. It does, however, discuss some tactics that should be considered. The information presented here and collected during pre-incident surveys should be used to train all emergency responders on how to properly handle incidents at facilities with combustible dust.

The information presented in this publication is limited to the fire and explosion hazards of combustible dust. Facilities with combustible dust may have other hazards for emergency responders to consider, such as engulfment, electric shock, unguarded machinery, and chemical toxins.

Also Read: What is the Difference between Intrinsically Safe and Flameproof Equipment?

How does a combustible dust explosion occur?

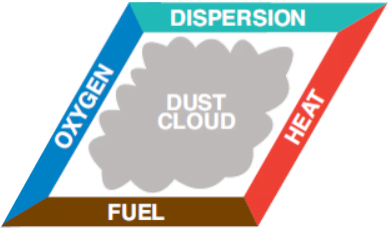

Firefighters are well aware of the elements of the “fire triangle”: fuel, heat, and oxygen (see figure 1).

In this case, combustible dust is the fuel. Oxygen is usually available in the ambient air. In addition to, or in place of oxygen, another chemical oxidizer may simulate oxygen in the combustion reaction. The following information discusses the additional elements needed for a flash fire or explosion to occur.

Read the book: Firefighting Precautions at Facilities with Combustible Dust by Flipping the file below:

Just about any solid material that burns can be

explosible when finely divided into dust. For example, a piece of wood can become explosible when reduced to sawdust. Even materials that do

not burn in larger pieces (such as aluminum or iron) can be explosible in dust form.

In school or training, you may have seen a demonstration involving a small container with flour or similar material that was ignited, creating a small fireball, and forced the lid of the container to lift. This can occur on a much larger scale in a building or confined space.

When combustible dust in the proper concentration is dispersed in a cloud, and then ignited, a flash fire occurs (see figure 2). This flash fire is like a larger version of the fireball in the classroom demonstration. It is much more dangerous to humans than an ordinary fire because it spreads too quickly to outrun. You may hear the term “deflagration”; this is a type of flash fire that is strong enough to cause damage to

equipment or structures.

When a flash fire is confined, the pressure that develops can cause an explosion, damaging or destroying the confining enclosure (see figure 3). This explosion is a larger version of the lifting lid in the classroom demonstration above. The confining enclosure could be processing equipment, a conveyor, a dust collector, a room,

or an entire building. The flying shrapnel, blast wave, and collapsing structural members resulting from the explosion can injure or kill individuals over a large area.

The blast wave can also disperse accumulated combustible dust in work or storage areas, fueling one or more subsequent explosions. These secondary explosions are often more destructive than the initial incident due to the large quantities of dust dispersed. Secondary explosions can continue to ignite in sequence, cascading throughout a facility.

Also Read: Tips to Avoid Fires and explosions at metal recycling Area

The Content of the: Firefighting Precautions at Facilities with Combustible Dust

- Introduction.

- How does a combustible dust explosion occur?

- What do previous incidents illustrate?

- What preparations can be made prior to a response?

- How should this preparation affect the operational plan?

- What precautions can be taken during a response?

- Where can I find additional information?

- Appendix A—Dust Collection Equipment

- Appendix B—Storage Methods

- Appendix C—Process Equipment

- Appendix D—Pneumatic Conveying Equipment

- OSHA Regional Offices

- How to Contact OSHA

( Also Read : Books: CAL/OSHA Pocket Guide for Construction Industry )

Download The Book

Firefighting Precautions at Facilities with Combustible Dust

More Downloads

- Books: How to Plan for Workplace Emergencies and Evacuation

- Books: Firefighting Precautions at Facilities with Combustible Dust

- Books: A Guide to Electrical Safety

- Books: Preventing Falls in Scaffolding Operations

- Handbook: Worker’s Safety

- Books: A Guide to Safety in Confined Spaces

- Books: OSHA-Hazard communication for small Entity

- Books: OSHA-Permit Required Confined Spaces

- OSHA: Underground Construction (Tunneling)

- OSHA Recommended Practice of Health and Safety programs in construction

- Books: OSHA-Is it Safe to Enter Confined Space?

- Books: General Industry Digest

- Books: A Guide to Bloodborne Pathogens in the workplace

- Books: 5-Minute Workplace Safety Talks

- CAL/OSHA Scaffold Guide for safe use of supported Scaffolds

- Books: CAL/OSHA Pocket Guide for Construction Industry

- Books: Let’s Talk Safety

- Books: OSHA Fall Protection Toolbox Talks and Trainer Guide