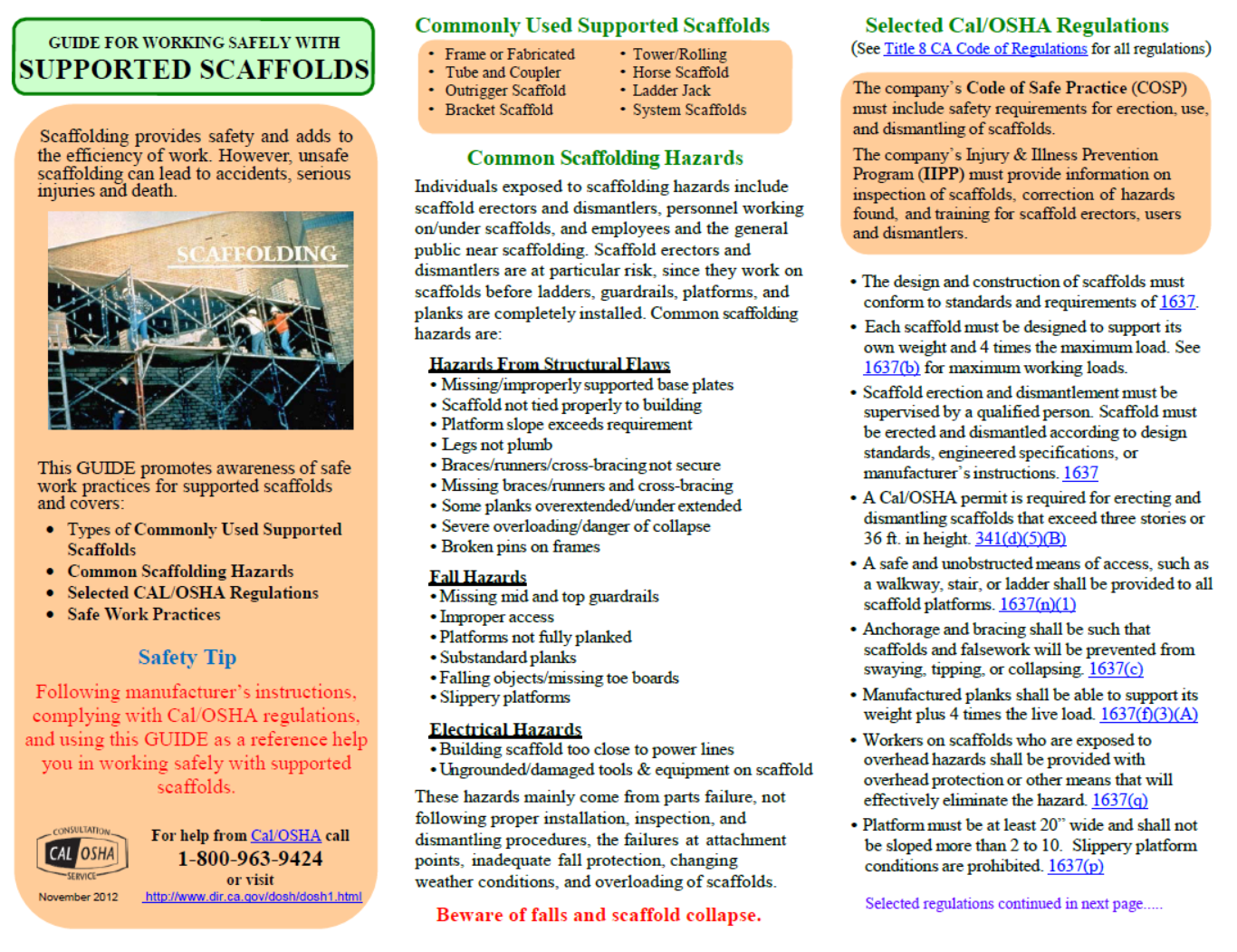

Scaffolding provides safety and adds to the efficiency of work. However, unsafe scaffolding can lead to accidents, serious injuries, and death.

This GUIDE promotes awareness of safe work practices for supported scaffolds and covers:

• Types of Commonly Used Supported Scaffolds

• Common Scaffolding Hazards

• Selected CAL/OSHA Regulations

• Safe Work Practices

Read the CAL/OSHA Scaffold Guide for safe use of supported Scaffolds Flipping book :

Commonly Used Supported Scaffolds

- Frame or Fabricated

- Tube and Coupler

- Outrigger Scaffold

- Bracket Scaffold

- Tower/Rolling

- Horse Scaffold

- Ladder Jack

- System Scaffolds

Common Scaffolding Hazards

Individuals exposed to scaffolding hazards include scaffold erectors and dismantlers, personnel working on/under scaffolds, and employees and the general public near scaffolding. Scaffold erectors and dismantlers are at particular risk since they work on scaffolds before ladders, guardrails, platforms, and planks are completely installed. Common scaffolding hazards are:

( Also Read: Books: CAL/OSHA Pocket Guide for Construction Industry)

Hazards From Structural Flaws

- Missing/improperly supported base plates

- Scaffold not tied properly to building

- Platform slope exceeds the requirement

- Legs not plumb

- Braces/runners/cross-bracing not secure

- Missing braces/runners and cross-bracing

- Some planks are overextended/under extended

- Severe overloading/danger of collapse

- Broken pins on frames

- Fall Hazards

- Missing mid and top guardrails

- Improper access

- Platforms not fully planked

- Substandard planks

- Falling objects/missing toe boards

- Slippery platforms

Electrical Hazards

- Building scaffolds too close to power lines

- Ungrounded/damaged tools & equipment on the scaffold

- These hazards mainly come from parts failure, not following proper installation, inspection, and dismantling procedures, failures at attachment points, inadequate fall protection, changing weather conditions, and overloading of scaffolds.

Safe Work Practices

Scaffolding accidents can occur during the erection, use, and dismantling of scaffolds. The following Safe Work Practices can help in preventing scaffold-related accidents.

Do these during scaffold design and selection:

- Select proper scaffold/scaffolding material.

- Follow proper design for constructed scaffold.

- Follow all requirements from the manufacturer.

- Follow all Title 8 design requirements.

- Have the stationary scaffolds over 125 feet in height and rolling scaffolds over 60 feet in height designed by a professional engineer.

Follow these during erection and dismantling:

- Scaffold and each level are maintained plumb.

- Scaffold is being erected under the direction of a qualified person.

- All employees involved with (or near) the scaffold wear hard hats.

- Footings are sound and rigid.

- Scaffolds are built from the bottom up and dismantled from the top down.

- The scaffold is secured to the structure during erection and dismantling.

- Ties to the structure are installed as soon as the scaffold is completed to each tie-in area.

- If platforms are sloped, the slope is no more than 2 feet vertical to 10 feet horizontal.

- Platforms are also secured so they can’t slip.

- When a platform turns a corner, planks are laid so as to avoid tipping.

- Guardrails on open sides/toeboards on all railed sides are provided as required.

- Proper access is provided.

- Electrical safety clearance distances are maintained and consideration for long materials such as gutters and pipes is given when determining clearances.

- Scaffold requirements for your trade are followed.

- Ties are removed only as the work progresses downward unless other methods are used to prevent the scaffold from falling over.

- When dismantling, structural members are not removed below the level being dismantled.

Do these during scaffold use:

- Has the scaffold been inspected by a qualified person before putting it into use?

- Inspect daily and before each use.

Also, Read Books: OSHA Fall Protection Toolbox Talks and Trainer Guide

Download The Guide

CAL/OSHA Scaffold Guide for safe use of supported Scaffolds

More Downloads

- Books: How to Plan for Workplace Emergencies and Evacuation

- Books: Firefighting Precautions at Facilities with Combustible Dust

- Books: A Guide to Electrical Safety

- Books: Preventing Falls in Scaffolding Operations

- Handbook: Worker’s Safety

- Books: A Guide to Safety in Confined Spaces

- Books: OSHA-Hazard communication for small Entity

- Books: OSHA-Permit Required Confined Spaces

- OSHA: Underground Construction (Tunneling)

- OSHA Recommended Practice of Health and Safety programs in construction

- Books: OSHA-Is it Safe to Enter Confined Space?

- Books: General Industry Digest

- Books: A Guide to Bloodborne Pathogens in the workplace

- Books: 5-Minute Workplace Safety Talks

- CAL/OSHA Scaffold Guide for safe use of supported Scaffolds

- Books: CAL/OSHA Pocket Guide for Construction Industry

- OSHA Programs: Aerial Lifts Safety Program-UK University

- Programs: Stairways and Ladders A Guide to OSHA Rules

- Books: Let’s Talk Safety

- Books: OSHA Fall Protection Toolbox Talks and Trainer Guide

- Booklet: Electrical Safety Worksite Do’s and Don’t