Combustible dust is a hazardous material that can lead to fires and explosions if not managed properly. It is a fine powder that can be generated from various materials such as wood, metal, plastic, and chemicals. When dust particles are suspended in the air, they can ignite and cause a fire or explosion. The Occupational Safety and Health Administration (OSHA) and the National Fire Protection Association (NFPA) have established guidelines and regulations to help prevent combustible dust incidents and protect workers. In this article, we will discuss combustible dust and firefighting precautions in accordance with OSHA and NFPA standards.

Also Read: Books: OSHA-Is it Safe to Enter Confined Space?

What is Combustible Dust?

Combustible dust is a hazard that can be present in many industries, including manufacturing, food processing, and chemical processing. It is defined as any finely divided solid material that is 420 microns or smaller in diameter and can catch fire and explode when mixed with air in certain concentrations. Some examples of materials that can generate combustible dust include:

- Wood and sawdust

- Metal powders, such as aluminum and magnesium

- Chemical dust, such as sulfur and sugar

- Agricultural dust, such as grain and tobacco

- Plastic dust, such as PVC and polystyrene

Combustible dust can be generated by various processes, including grinding, sanding, polishing, and cutting. It can also accumulate on surfaces and equipment, leading to a potential fire or explosion hazard.

Read E-Books: Firefighting Precautions at Facilities with Combustible Dust

OSHA Regulations on Combustible Dust:

OSHA has established regulations to help prevent combustible dust incidents and protect workers. The General Duty Clause of the Occupational Safety and Health Act requires employers to provide a workplace free from recognized hazards that can cause death or serious physical harm to employees. OSHA also has specific regulations that address combustible dust hazards, including:

- 29 CFR 1910.22 – General Requirements for Housekeeping

This regulation requires employers to maintain a clean and orderly workplace to minimize the accumulation of combustible dust. - 29 CFR 1910.119 – Process Safety Management

This regulation requires employers to develop and implement a process safety management program to control hazards associated with processes involving highly hazardous chemicals, including combustible dust. - 29 CFR 1910.307 – Hazardous (Classified) Locations

This regulation establishes requirements for electrical equipment in hazardous locations where combustible dust may be present. know more about the classification of combustible dust below

The classification of combustible dust

The classification of combustible dust is an important step in identifying the potential hazards associated with these materials. The National Fire Protection Association (NFPA) has established a system for classifying combustible dusts based on their physical and chemical properties. This system helps to identify the potential hazards associated with combustible dust and determine appropriate safety measures to prevent incidents.

The NFPA classifies combustible dust into three categories:

- Class II – Dust with Moderate Explosion Hazards

Class II combustible dust has a moderate explosion hazard and requires special precautions to prevent fires and explosions. These types of dust include wood, plastics, and some metals. - Class III – Dust with Low Explosion Hazards

Class III combustible dust has a low explosion hazard and requires less stringent safety measures than Class II dust. These types of dust include food products, paper, and some textiles. - Class I – Dust with High Explosion Hazards

Class I combustible dust has a high explosion hazard and requires the most stringent safety measures to prevent fires and explosions. These types of dust include metals such as aluminum and magnesium, as well as sulfur and other chemicals.

In addition to these three classes, the NFPA also classifies combustible dust based on its ignition sensitivity and explosion severity. This information is used to determine the appropriate safety measures for handling and storing these materials.

The ignition sensitivity of combustible dust refers to how easily the dust can be ignited. Dust that is more easily ignited requires more stringent safety measures to prevent fires and explosions. The NFPA classifies combustible dust based on its minimum ignition energy (MIE), which is the minimum energy required to ignite the dust.

The explosion severity of combustible dust refers to the potential damage that can be caused by an explosion. Dust that can cause more severe explosions requires more stringent safety measures to prevent fires and explosions. The NFPA classifies combustible dust based on its maximum explosion pressure (MEP) and maximum rate of pressure rise (dP/dt).

Overall, the classification of combustible dust is an important step in identifying potential hazards and determining appropriate safety measures to prevent fires and explosions. It is essential that employers follow the NFPA guidelines and regulations to ensure the safety of their workers and prevent incidents related to combustible dust.

What safety measures are required for Class I combustible dust?

Class I combustible dust has a high explosion hazard and requires the most stringent safety measures to prevent fires and explosions. To protect workers and prevent incidents related to these materials, employers must follow the guidelines and regulations established by the National Fire Protection Association (NFPA) and the Occupational Safety and Health Administration (OSHA). Some of the safety measures required for Class I combustible dust include:

- Hazardous Area Classification

Employers must properly classify the area where Class I combustible dust is present as a hazardous location. This involves conducting a hazard assessment to determine the likelihood of a fire or explosion and the extent of the hazard zone. Hazardous locations must be properly labeled and marked to alert workers to potential hazards. - Equipment Selection and Installation

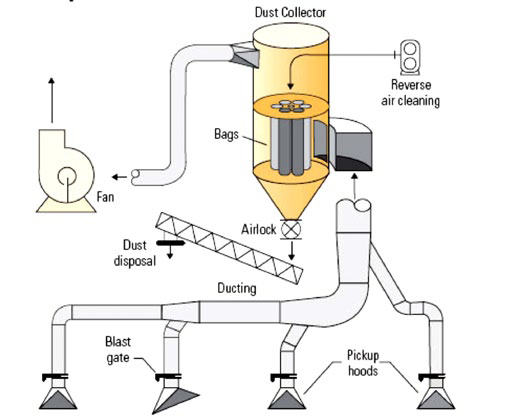

Electrical equipment installed in hazardous locations must be designed and installed to prevent the ignition of combustible dust. This includes the use of explosion-proof or dust-tight enclosures, grounding and bonding, and proper sealing around openings. - Housekeeping

Proper housekeeping is essential to prevent the accumulation of combustible dust. Employers must establish and implement a housekeeping program that includes regular cleaning of floors, walls, and equipment to prevent the buildup of dust. This may involve the use of vacuum systems or other methods that minimize the generation of dust. - Ignition Source Control

Employers must take steps to eliminate potential ignition sources in areas where Class I combustible dust is present. This may include the use of non-sparking tools, the elimination of smoking and open flames, and the use of static grounding devices. - Employee Training

Employers must provide training to employees on the hazards of combustible dust and the safety measures required to prevent fires and explosions. This includes training on proper handling and storage of combustible dust, the use of personal protective equipment, and emergency response procedures. - Ventilation

Proper ventilation is essential to prevent the buildup of combustible dust and reduce the risk of a fire or explosion. Employers must ensure that ventilation systems are properly designed, installed, and maintained to control the accumulation of combustible dust and prevent the spread of a fire or explosion.

Overall, the safety measures required for Class I combustible dust are stringent and require careful attention to detail. Employers must follow the guidelines and regulations established by the NFPA and OSHA to protect workers and prevent incidents related to these hazardous materials.

Read more: How to control the Dust-On Tool Extractio

Firefighting Precautions:

Firefighting in a combustible dust environment requires special precautions to prevent the situation from escalating into a catastrophic event. Some firefighting precautions that should be taken in a combustible dust environment include:

- Use of Appropriate Fire Extinguishers

Fire extinguishers should be selected based on the type of material involved in the fire. For example, Class D fire extinguishers should be used for fires involving metal powders, while Class A or B fire extinguishers may be appropriate for fires involving other types of combustible dust.

- Avoid the Use of Water

Water should not be used to extinguish combustible dust fires as it can disperse the dust and increase the risk of an explosion. - Use of Inerting Agents

Inerting agents, such as carbon dioxide and nitrogen, can be used to displace oxygen and prevent the combustion of combustible dust. - Proper Ventilation

Proper ventilation is essential to prevent the buildup of combustible dust and reduce the risk of a fire or explosion.

Read More: Quick Guide to Control wood dust hazards at Work

Conclusion:

Combustible dust is a hazardous material that can cause fires and explosions if not managed properly. OSHA and NFPA have established regulations and standards to help prevent combustible dust incidents and protect workers. Firefighting in a combustible dust environment requires special precautions, including the use of appropriate fire extinguishers, avoidance of water, use of inerting agents, and proper ventilation. By following these guidelines and regulations, employers can help prevent combustible dust incidents and protect the safety of their workers.