Construction Safety and Health Management Program industry guide is designed to assist employers in the construction industry in developing a comprehensive safety and health program with best practices to be tailored to your own operation. We encourage you to customize the information in this industry guide as necessary to accomplish this goal. You may also copy any of the material in this guide to be used in your safety and health efforts. This guide is provided as a best practice and compliance aid. It does not constitute a legal interpretation of OSHA standards, nor does it replace the need to be familiar with and follow the actual OSHA standards. Though the programs contained in this document are intended to be consistent with OSHA standards, if an area is considered by the reader to be inconsistent, the OSHA standard should be followed.

Please note that this guide may not include all the programs and policies that may be required by OSHA standards or as a best practice for your specific operation or industry. It may also include more programs than are needed for your operation.

Also Read: Model High Hazard Safety Program

Section 1

Safety and Health Program Management

Safety and Health Policy

Note: The following section is a best practice. Please modify or delete content to these policies as deemed necessary

We place a high value on the safety and health of our employees. We are committed to providing a safe workplace for all employees and have developed this program for injury prevention to involve management, supervisors, and employees in identifying and eliminating hazards that may develop during our work process.

It is the basic safety and health policy of this company that no task is so important that an employee must violate a safety and health rule or take a risk of injury or illness to get the job done.

Employees are required to comply with all company safety and health rules and are encouraged to actively participate in identifying ways to make our company a safer place to work.

Supervisors are responsible for the safety and health of their employees and, as a part of their daily duties, must check the workplace for unsafe conditions, watch employees for unsafe actions and take prompt action to eliminate any hazards.

Management will do its part by devoting the resources necessary to form a safety and health committee composed of management and elected employees. We will develop a system for identifying and correcting hazards. We will plan for foreseeable emergencies. We will provide initial and ongoing training for employees and supervisors and we will establish a disciplinary policy to ensure that company safety and health policies are followed.

Safety and Health Responsibilities

Note: The following section is a best practice. Please modify or delete content to these policies as deemed necessary

Manager Responsibilities

- Ensure that sufficient employee time, supervisor support, and funds are budgeted for equipment, training, and carrying out the safety and health program.

- Evaluate supervisors each year to make sure they carry out their responsibilities as described in this program.

- Ensure that incidents are fully investigated and corrective action is taken to prevent the hazardous conditions or behaviors from happening again.

- Ensure that a record of injuries and illnesses is maintained and posted as described in this program.

- Set a good example by following established safety and health rules and attending required training.

- Report unsafe practices or conditions to the supervisor of the area where the hazard was observed.

Supervisor Responsibilities

- Ensure that each employee has received initial orientation before beginning work.

- Ensure that each employee is competent or has received training on the safe operation of equipment or tasks before starting work.

- Ensure that each employee receives the required personal protective equipment (PPE) before starting work on a project requiring PPE.

- Perform a daily safety check of the work area. Promptly correct any hazards you find.

- Observe the employees you supervise while they are working. Promptly correct any unsafe behavior. Provide additional training and take corrective action as necessary.

- Document employee evaluations.

- Set a good example for employees by following the safety and health rules and attending required training.

- Investigate all incidents in your area and report findings to management.

- Talk to management about changes to work practices or equipment that will improve employee safety and health.

Employee Responsibilities

- Follow the safety and health rules established by your company, Report unsafe conditions or actions to your supervisor or safety and health committee representative promptly.

- Report all work-related injuries and illnesses to your supervisor promptly, regardless of how minor they may seem.

- Report all near-miss incidents to your supervisor promptly.

- Always use personal protective equipment that is in good working condition when it is required.

- Do not remove or bypass any safety device or safeguard provided for your protection.

- Encourage your co-workers to use safe work practices on the job.

- Make suggestions to your supervisor, safety, and health committee representative, or management about changes that will improve employee safety and health.

Employee Participation

Note: The following section is a best practice. Please modify or delete content to these policies as deemed necessary

Note: While safety and health committees are not required by law, the following can be used as a statement when the company has a voluntary safety and health committee and is an example of how the committee members may be selected and function within the company. Alternative methods may be used as well.

Safety and Health Committees and Meetings

Employers can form safety and health committees to help employees and management work together to identify safety and health problems, develop solutions, review incident reports, and evaluate the effectiveness of the safety and health program. The committee should be made up of management-designated representatives and employee-elected representatives from all areas within the company.

Employees from each operational unit, division, or area may volunteer or be nominated from among themselves to be a representative on the committee. If there is only one volunteer or nomination, the employees may approve the person by voice vote at a short meeting called for that purpose. If there is more than one volunteer or nomination, a secret paper ballot may be used to elect the representative.

Elected representatives will serve for (Insert the number of years) year(s) before being re-elected or replaced. If there is a vacancy then an election will be held before the next scheduled meeting to fill the balance of the term. (It is recommended that members serve two years, with half of the members replaced after the first year when the initial committee is formed so that there are carry-over members on the committee at all times).

In addition to the employee-elected representatives, management should designate no more than three representatives but a minimum of one who will serve until replaced by management. Management representation should not outnumber employee representation. If the company employs a medical professional on staff, it is recommended that this individual serves on the safety and health committee as well but at least an individual who manages the workers’ compensation, injury and illness, and first aid logs, such as the company safety and health manager.

A chairperson should be selected by a majority vote by the committee members each year. If there is a vacancy, the same method should be used to select a replacement.

The duties of safety and health committee members include:

- Conducting a monthly self-inspection of the area they represent.

- Communicating with the employees they represent on safety and health issues.

- Encouraging safe work practices among co-workers.

- Reviewing the injury, illness, and first aid logs for trends and conducting a separate investigation of any incident (if determined appropriate).

- Providing any recommendations to management for consideration.

The safety and health committee should meet at least (Insert frequency). Each area committee member should bring information from the monthly inspections of their areas and any concerns from the employees in the area they represent. Using this information, the committee can help identify safety and health problems, develop solutions, review incident reports, provide training, and evaluate the effectiveness of the safety and health program. A committee member will be designated to keep minutes. A copy of the minutes will be posted in a place where all affected employees have access to them. The company should archive meeting minutes for a specified period of time such as one year for follow-up/review purposes. (The company may choose to post minutes on employee bulletin boards, on an intranet, etc. Additionally, the company may choose to archive such records electronically.)

General Employee Safety Meetings

All employees are required to attend a monthly safety and health meeting. This meeting will help identify safety and health problems, develop solutions, provide training, and evaluate the effectiveness of the safety and health program.

An employee will be designated each month to keep the minutes. A copy of the minutes will be posted in a place where all affected employees have access to them. The company should archive meeting minutes for a specified period of time such as one year for follow-up/review purposes. (The company may choose to post minutes on employee bulletin boards, on an intranet, etc. Additionally, the company may choose to archive such records electronically).

Recordkeeping and Reporting

Note: The following section contains workers’ compensation procedures and OSHA recordkeeping requirements

Injuries and Illnesses Reporting

Employees are required to report any injury or work-related illness to their immediate supervisor regardless of how serious. Minor injuries such as cuts and scrapes will be entered on the first aid log. The employee will use an “Employee’s Incident Report” form (or Workers’ Compensation Form 18) to report more serious/compensable injuries.

The supervisor will:

- Investigate all injuries and illnesses in their work area, including serious first-aid cases and near-miss incidents. Complete an “Incident Investigation Report” form and “Supervisor’s Incident Investigation” form immediately following the incident.

- Provide all incident investigation report forms to the safety and health manager/company medical professional or HR/personnel office within three days of the incident.

The safety and health manager/company medical professional/HR or personnel manager will:

- Determine from the Employee’s Incident Report form, Incident Investigation Report form, and any claim form associated with the incident whether it must be recorded on the OSHA 300 Injury and Illness Log and Summary according to the instructions for that form.

- Enter any recordable incident within seven calendar days after becoming aware of the injury/illness/fatality.

- If the injury is not recorded on the OSHA log, add it to the first aid log, which is used to record non-OSHA recordable injuries and near misses.

- The employer may need to fill out and file a Workers’ Compensation Form 19, “Employer’s Report of Employee’s Injury,” with the Industrial Commission within five days of learning of an injury or allegation. If Form 19 is filed with the Industrial Commission, the employer must provide a copy of Form 19 to the employee, together with a blank Form 18, “Notice of Accident to Employer and Claim of Employee,” for use by the employee. (http://www.ic.nc.gov/)

A signed copy of the OSHA log summary (OSHA Form 300A) for the previous year must be posted on the safety bulletin board from Feb. 1 through April 30. The log must be kept on file for at least five years. Any employee can view an OSHA log upon request at any time during the year.

Employee Access to Medical and Exposure Records (1926.33(a), 1926.33(b)(3))

Whenever an employee or designated representative requests access to a record, we must ensure that access is provided in a reasonable time, place, and manner. If we cannot reasonably provide access to the record within 15 working days, we will appraise the employee or designated representative requesting the record of the reason for the delay and the earliest date when the record can be made available.

The medical record for each employee will be preserved and maintained for at least the duration of employment plus 30 years.

First aid records (not including medical histories) of one-time treatment and subsequent observation of minor scratches, cuts, burns, splinters, and the like that do not involve medical treatment, loss of consciousness, restriction of work or motion, or transfer to another job, if made on-site by a nonphysician and if maintained separately from the employer’s medical program and its records and the medical records of employees who have worked for less than one year for the employer need not be retained beyond the term of employment if they are provided to the employee upon the termination of employment.

Exposure Records

Background data for environmental (workplace) monitoring or measuring, such as laboratory reports and worksheets, need only be retained for one year so long as the sampling results, the collection methodology (sampling plan), a description of the analytical and mathematical methods used, and a summary of other background data relevant to the interpretation of the results obtained are retained for at least 30 years.

Material safety data sheets and records concerning the identity of a substance or agent need not be retained for any specified period as long as some record of the identity (chemical name if known) of the substance or agent, where it was used, and when it was used is retained for at least 30 years.

Biological monitoring results designated as exposure records by specific occupational safety and health standards must be preserved and maintained as required by the specific standard.

Analyses using exposure or medical records must be preserved and maintained for at least 30 years.

Training Records

Some standards require training records to be maintained for three years and some do not require training records. Records of employees who have worked for less than one year need not be retained after employment, but we are required to provide these records to the employee upon termination of employment. Our policy is to maintain training records for (insert time frame).

Accident/Incident Investigation

Note: The following section is a best practice. Please modify or delete content to these policies as deemed necessary.

Accident/Incident Investigation

Accident/Incident Investigation Procedures

If an employee dies while working or within 30 days of the initial accident/incident causing an injury or illness, or when three or more employees are admitted to the hospital as a result of a work-related accident/incident, the company must contact the N.C. Department of Labor’s OSH Division within eight hours of becoming aware of the accident/incident. The toll-free notification number is 1-800-NC-LABOR (1-800-625-2267).

Whenever there is an incident that results in death or serious injuries or illnesses, a preliminary investigation will be conducted by an accident investigation team made up of the immediate supervisor of the injured person(s), a person designated by management, an employee representative of the safety and health committee, and any others whose expertise would help in the investigation.

The accident investigation team will take written statements from witnesses and photograph the incident scene and equipment involved. The team will also document, as soon as possible after the incident, the condition of equipment and any anything else in the work area that may be relevant. The team will complete a written incident investigation report. The report will include a sequence of events leading up to the incident, conclusions about the incident and any recommendations to prevent a similar incident in the future. This report will be given to [insert appropriate name/job title] for corrective action. The report will be reviewed by the safety and health committee at its next regularly scheduled meeting.

Also Read: Hazard Identification Plan (HIP) Template

When a supervisor becomes aware of an employee injury where the injury was not serious enough to warrant a team investigation as described above, the supervisor will write an incident investigation report to accompany the employee’s report and forward them to [insert appropriate name/job title].

In addition, whenever there is an incident that did not result in an injury to an employee (a near miss), the supervisor will investigate the incident. The incident investigation report form will be filled out to investigate the near miss and to establish any corrective action as applicable. The form will be clearly marked to indicate that it was a near miss and that no actual injury occurred. The report will be forwarded to [insert appropriate name/job title] to record on the incident log and for further action.

Employee’s Incident Report Form

Instructions: Employees will use this form to report all work-related injuries, illnesses, or “near miss” events (which could have caused an injury or illness)—no matter how minor. This helps to identify and correct hazards before they cause serious injuries. This form will be completed by employees as soon as possible and given to a supervisor for further action. (NCIC Form 18 may be used in place of this one.)

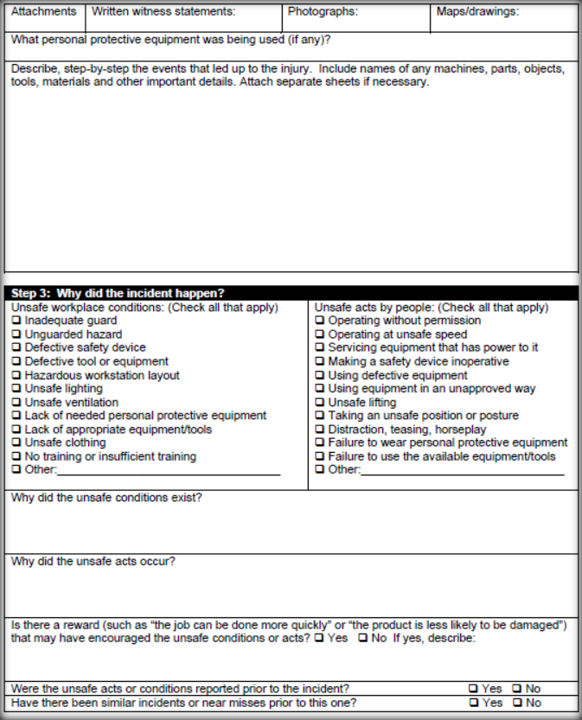

Incident Investigation Report

Instructions: Complete this form as soon as possible after any incident that an employee reports or which results in serious injury or illness and investigate a minor injury or near miss that could have resulted in a serious injury or illness.

Safety and Health Inspection Procedures

We are committed to aggressively identifying hazardous conditions and practices that are likely to result in injury or illness to employees. We will take prompt action to eliminate any hazards we find. In addition to reviewing injury records and investigating incidents for their causes, management and the safety committee will regularly check the workplace for hazards as described below.

All contractors performing work will be responsible for conducting daily safety inspections of their work area, tools, and equipment. The following inspections will be required as they relate to the ongoing work activities:

General Worksite Safety and Health

Our company and each subcontractor will perform a general safety and health inspection of their respective work areas on a daily basis.

Scaffold Safety

Subcontractors that use scaffolds will have a designated competent person to inspect their scaffolds prior to use each.

Trenches and Excavations

Subcontractors that work in trenches or excavations will have a designated competent person to inspect their excavations prior to beginning work each day.

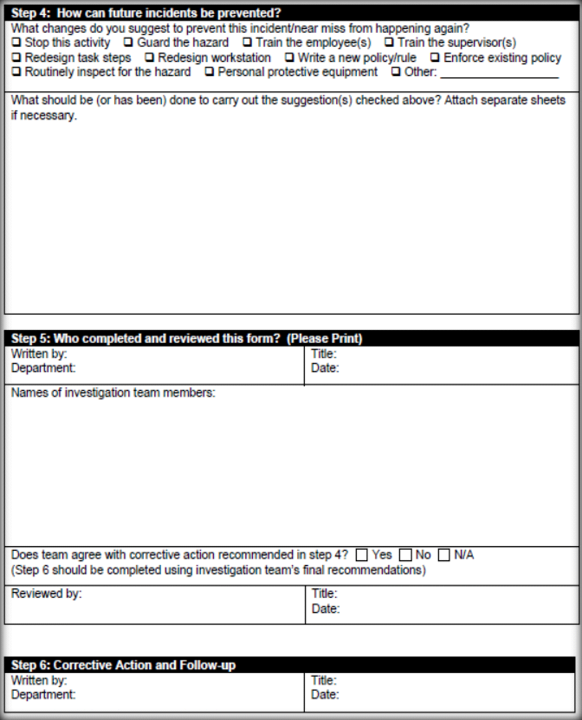

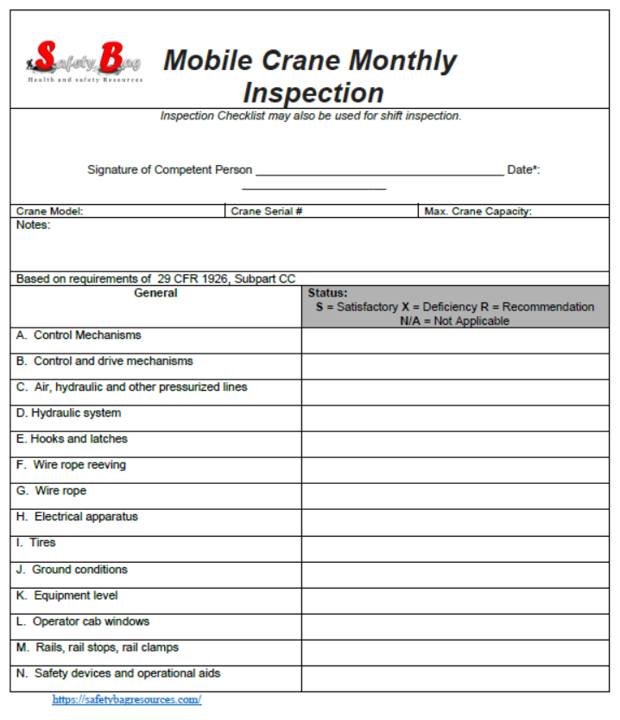

Cranes

Subcontractors using cranes on the job site will have a designated competent person to inspect each crane prior to use each day.

Forklifts

Subcontractors using forklifts on the job site will have a designated competent person to inspect each forklift prior to use each day.

Manlifts and Scissor Lifts

Subcontractors using manlifts or scissor lifts will have a designated competent person inspect all mechanical parts of such lifts, including all welds for signs of fatigue prior to use each day.

Also Read: Construction Safety Inspection Checklist

Disciplinary Policy

Note: The following section is a best practice. Please modify or delete content to these policies as deemed necessary.

The company has established a progressive disciplinary program for those acts or practices not considered immediately dangerous to life or health. Unsafe acts will not be tolerated. Each employee has an individual responsibility to work safely. We have established a progressive disciplinary program for those acts or practices not considered immediately dangerous to life or health.

(Note: The following are examples of disciplinary actions. Employers may wish to establish these policies as part of their general personnel policies and should seek legal advice prior to implementing them in the workplace.)

| First Instance | Warning, notation in employee file,, and instruction on proper actions. |

| Second Instance | Written reprimand and instruction on proper actions. |

| Third Instance | One- to a five-day suspension, written reprimand, and instruction on proper actions. |

| Fourth Instance | Termination of employment. |

Other-than-serious safety violations may consist of, but are not limited to:

- Failure to wear hard hat.

- Failure to wear safety glasses/eye protection.

- Failure to use hearing protection.

- Failure to wear appropriate boots and clothing.

- Chemical containers not labeled.

- Failure to attend orientation training.

- Failure to report an accident.

An employee may be subject to immediate termination when a safety or health violation places the employee or co-workers at risk of permanent disability or death. These include but are not limited to:

- Failure to follow fall protection requirements.

- Failure to wear required respiratory protection.

- Failure to follow the substance abuse policy.

- Failure to wear a protective vest when working on or near a city street.

- Possession of firearms, explosives or dangerous weapons.

- Violation of project security rules or procedures.

- Fighting, horseplay, practical joking or gambling.

- Entering a confined space without following procedures.

- Unsafe or reckless operation of motorized vehicles or equipment.

- Failure to follow lockout/tagout procedures.

- Failure to follow hot work permit procedures.

Alcohol and Drug Use Policy

Note: The following section is a best practice. It is an example of a drug testing and alcohol and drug use policy. Employers may wish to establish these policies as part of their general personnel policies and should seek legal advice prior to implementing them in the workplace.

We have a vital interest in maintaining safe, healthy, and efficient working conditions for our employees. Therefore, the use of substances that impair an employee’s ability to perform the job safely is not allowed. The use of these substances (except legally prescribed drugs reported to the supervisor/employer) during duty hours is prohibited, and their use may result in disciplinary action. Duty hours consist of all working hours, including break periods and on-call periods, whether on or off company premises.

The consumption of alcohol or illegal drugs while performing company business or while in a company facility or vehicle is prohibited and will result in disciplinary action up to and including termination of employment. Additionally, employees must report to their supervisor the use of legally prescribed drugs (such as narcotics) that may affect their ability to perform any part of their job safely so that alternate assignments/duties may be considered when necessary. Failure to report this type of drug use may also result in disciplinary action under certain circumstances.

Drug testing will be performed after all accidents that occur on company time or property or in or on a company owned vehicle or other equipment. Additionally, random drug testing may be performed if employees are suspected of being under the influence of alcohol or any illegal drug and when they appear to be impaired by any substance, including unreported use of legally prescribed medications, while at work. Refusal to submit to a drug test after an accident/incident may result in termination of employment.

Section 2

Safety and Health Programs

Note

Note: The following pages contain example safety and health programs and policies that may be applicable to your company. It is the responsibility of the company to determine whether these programs are mandatory in your work environment based on the scope and application of the referenced standard. Every effort has been made to include the content required by standards. Additionally, other good practices have been included that may or may not apply to your company.

Please add or delete content to these programs as deemed necessary. While most standards do not require a program administrator or coordinator, it is a good practice to have an employee who is knowledgeable and appropriately trained assigned to administer and review these programs on a continuing basis to ensure their effectiveness in the workplace. Individuals such as human resource professionals, risk managers, safety managers, industrial hygienists, and medical professionals are the most appropriate to administer these programs. Additionally, safety and health committees and other suitably trained and experienced employees may also help administer and review these programs

Aerial Lifts (Ref. 29 CFR 1926.453–454)

Note: The following written policy is based on the referenced standard. The standard does not require your policy to be in writing, but as a best practice, it has been put into writing in this manual. Please modify or delete content to the policy as deemed appropriate for your worksite. The standard should be referenced to ensure that all requirements are being met.

Aerial lifts, powered or manual, include but are not limited to, the following types of vehicle-mounted aerial devices used to elevate personnel to job sites above ground: extensible boom platforms, articulating boom platforms, and vertical towers.

When operating aerial lifts, we will ensure that our employees are:

- Trained.

- Authorized.

- Setting brakes and using outriggers.

- Not exceeding boom and basket load limits.

- Using personal fall protection when required.

- Not using devices such as ladders, stilts or step stools to raise the employee above the basket.

In addition, manufacturers or the equivalent must certify in writing all modifications to aerial lifts.

Asbestos (Ref. 29 CFR 1926.1101)

Note: The following program is an example of a written policy based on the referenced standard. The standard does not require it to be in writing, but as a best practice, it has been put into writing in this manual. Please modify or delete content to the policy as deemed appropriate for your worksite. The standard should be referenced to ensure that all requirements are being met.

Exposure Monitoring

We will perform monitoring whenever a workplace or work operation requires exposure to accurately determine the airborne concentrations of asbestos to which our employees may be exposed.

Based on the monitoring results, we will ensure that no employee is exposed to an airborne concentration of asbestos in excess of 0.1 fibers per cubic centimeter (f/cc) as an 8-hour time-weighted average (TWA). In addition, we will ensure that no employee is exposed to an airborne concentration of asbestos in excess of 1 f/cc as averaged over a sampling period of 30 minutes.

Respirators

Respirators will be used during (1) all Class I asbestos jobs; (2) all Class II work where asbestos-containing material is not removed substantially intact; (3) all Class II and III work not using wet methods, except on sloped roofs; (4) all Class II and III work without a negative exposure assessment; (5) all Class III jobs where thermal system insulation or surfacing asbestos-containing or presumed asbestos-containing material is cut, abraded, or broken; (6) all Class IV work within a regulated area where respirators are required; (7) all work where employees are exposed above the PEL or STEL; and (8) in emergencies.

Personal Protective Equipment

We will provide and require the use of protective clothing—such as coveralls or similar whole-body clothing, head coverings, gloves, and foot coverings—for

- Any employee exposed to airborne asbestos exceeding the PEL or STEL,

- Work without a negative exposure assessment, or

- Any employee performing Class I work involving the removal of over 25 linear or 10 square feet (0.93 square m) of thermal system insulation or surfacing asbestos-containing or presumed asbestos-containing materials.

Medical Surveillance We will provide a medical surveillance program for all employees who, for a combined total of 30 or more days per year, engage in Class I, II, or III work or are exposed at or above the PEL or STEL, or who wear negative pressure respirators.

Compressed Gas Cylinders (Ref. 29 CFR 1926.350)

Note: The following written policy is based on the referenced standard. The standard does not require your policy to be in writing, but as a best practice, it has been put into writing in this manual. Please modify or delete content to the policy as deemed appropriate for your worksite. The standard should be referenced to ensure that all requirements are being met.

Safe Work Practices

- Compressed air used for cleaning purposes must be reduced to less than 30 pounds per square inch (psi) (207 kPa) and then only with effective chip guarding and personal protective equipment.

- Valve protection caps must be in place and secured when compressed gas cylinders are transported, moved, or stored.

- Cylinder valves must be closed when work is finished and when cylinders are empty or moved.

- Compressed gas cylinders must be secured in an upright position at all times, except if necessary for short periods of time when cylinders are actually being hoisted or carried.

- Cylinders must be kept far enough away from the actual welding or cutting operations so that sparks, hot slag, or flame will not reach them. When this is impractical, fire-resistant shields must be provided. Cylinders must be placed where they cannot become part of an electrical circuit.

Oxygen and fuel gas pressure regulators must be in proper working order while in use.

Concrete and Masonry (Ref. 1926.701)

Note: The following written policy is based on the referenced standard. The standard does not require your policy to be in writing, but as a best practice, it has been put into writing in this manual. Please modify or delete content to the policy as deemed appropriate for your worksite. The standard should be referenced to ensure that all requirements are being met.

Safe Work Practices

- Construction loads must not be placed on a concrete structure or portion of a concrete structure unless the employer determines, based on information received from a person who is qualified in structural design, that the structure or portion of the structure is capable of supporting the loads.

- Employees must not be permitted to work under concrete buckets while buckets are being elevated or lowered into position.

- To the extent practical, elevated concrete buckets must be routed so that no employee or the fewest number of employees is exposed to the hazards associated with falling concrete buckets.

- Formwork must be designed, fabricated, erected, supported, braced and maintained so that it is capable of supporting without failure all vertical and lateral loads that may reasonably be anticipated to be applied to the formwork.

- Forms and shores (except those used for slabs on grade and slip forms) must not be removed until the employer determines that the concrete has gained sufficient strength to support its weight and superimposed loads. Such determination must be based on complying with one of the following:

- The plans and specifications stipulate conditions for the removal of forms and shores, and such conditions have been followed, or

- The concrete has been properly tested with an appropriate American Society for Testing Materials (ASTM) standard test method designed to indicate the concrete compressive strength, and the test results indicate that the concrete has gained sufficient strength to support its weight and superimposed loads. (ASTM, 100 Barr Harbor Drive, West Conshohocken, PA 19428; 610-832-9585). 1926.703(e)(1)(i)–(ii).

A limited access zone will be established whenever a masonry wall is being constructed. The limited access zone must conform to the following:

- The limited access zone must be established prior to the start of the construction of the wall.

- The limited access zone must be equal to the height of the wall to be constructed plus 4 feet (1.2 m) and must run the entire length of the wall.

- The limited access zone must be established on the side of the wall that will not have a scaffold

- The limited access zone must be restricted to entry by employees actively engaged in constructing the wall. Other employees must not be permitted to enter the zone.

- The limited access zone must remain in place until the wall is adequately supported to prevent overturning and to prevent collapse. Where the height of a wall is more than 8 feet (2.4 m), the limited access zone must remain in place until the requirements of 1926.706(b) have been met.

All masonry walls more than 8 feet (2.4 m) in height will be adequately braced to prevent overturning and to prevent collapse unless the wall is adequately supported so that it will not overturn or collapse. The bracing will remain in place until permanent supporting elements of the structure are in place.

Confined Space (Ref. 29 CFR 1926.21)

Note: The following program is an example of a written policy and based on the referenced standard. The standard does not require it to be in writing, but as a best practice, it has been put into writing in this manual. Please modify or delete content to the policy as deemed appropriate for your worksite. The standard should be referenced to ensure that all requirements are being met.

We will comply with all regulations that apply to work in dangerous or potentially dangerous areas.

Confined or enclosed spaces include, but are not limited to, storage tanks, process vessels, bins, boilers, ventilation or exhaust ducts, sewers, underground utility vaults, tunnels, pipelines, and open top spaces more than 4 feet deep (1.2 m) such as pits, tubs, vaults, and vessels.

Policy

All spaces that meet the definition of permit-required confined spaces (PRCS) will be identified and appropriately marked. We will control access to these spaces.

Employees are prohibited from entering any space meeting the definition of a PRCS unless the following conditions are met:

- The company determines that employees must enter permit-required confined spaces to perform assigned duties. The employees are trained to safely perform these duties in a PRCS.

The confined space is rendered safe for entry:

- By issuance and compliance with the conditions of a permit.

- When the space is reclassified as a non-permit space without making entry into the space. (This does not apply to a PRCS with an actual or potential hazardous atmosphere.)

- Alternate entry procedures are performed.

Permits issued under the procedures in this policy will be limited to the duration of the job but no longer than one work shift. A new permit is required if work continues on a second shift or another day.

Definitions

Confined Space—a space that meets all three of the following conditions:

- Is large enough and so configured that an employee can bodily enter and perform assigned work.

- Has limited or restricted means for entry or exit (for example, tanks, vessels, silos, storage bins, hoppers, vaults, and pits are spaces that have limited means of entry).

- Is not designed for continuous human occupancy.

Permit Required Confined Space (Permit Space)—a confined space that has one or more of the following characteristics:

- Contains or has the potential to contain a hazardous atmosphere.

- Contains a material that has the potential for engulfing an entrant.

- Has an internal configuration such that the entrant could be trapped or asphyxiated by inwardly converging walls or a floor that slopes downward and tapers to a smaller cross-section.

- Contains any other recognized serious safety or health hazard.

Duties and Responsibilities

Authorized Attendant. The trained individual stationed outside the permit space monitors the authorized entrants and performs all attendant duties. The attendant will:

- Remain outside the permit space during entry operations unless relieved by another authorized attendant.

- Perform non-entry rescues when specified by the company’s rescue procedure.

- Know existing and potential hazards, including information on the mode of exposure, signs or symptoms, consequences, and physiological effects.

- Maintain communication with and keep an accurate account of those workers entering the permit space.

- Order evacuation of the permit space when a prohibited condition exists; when a worker shows signs of physiological effects of hazard exposure; when an emergency outside the confined space exists; and when the attendant cannot effectively and safely perform required duties.

- Summon rescue and other services during an emergency.

- Ensure that unauthorized people stay away from permit spaces or exit immediately if they have entered the permit space.

- Inform authorized entrants and the entry supervisor if any unauthorized person enters the permit space.

- Perform no other duties that interfere with the attendant’s primary duties.

Authorized Entrant. The trained individual enters the permit space. The entrant is required to:

- Know space hazards, including information on the means of exposure such as inhalation or dermal absorption, signs and symptoms, and consequences of the exposure.

- Use appropriate personal protective equipment properly.

- Maintain communication with attendants as necessary to enable them to monitor the entrant’s status and alert the entrant to evacuate when necessary.

- Exit from the permit space as soon as possible when ordered by the attendant; when he or she recognizes the warning signs or symptoms of exposure; when a prohibited condition exists; or when an automatic alarm is activated.

- Alert the attendant when a prohibited condition exists or when warning signs or symptoms of exposure exist.

Entry Supervisor. The trained individual with the responsibility to assure that acceptable entry conditions are present within a permit space under his or her jurisdiction; issuing a permit authorizing entry; overseeing entry operations; and terminating the entry and permit.

For each entry into a PRCS, the designated entry supervisor will:

- Perform the pre-entry duties of the entry supervisor on the permit space to be entered.

- Prepare an entry permit, reclassify the space as a non-permit space, or authorize alternate entry procedures in compliance with the relevant procedures of this program.

- Perform the post-entry duties of the entry supervisor.

- Collect the permit from the attendant at the end of the entry, or prepare the documentation for reclassification or alternate entry.

For the duration of each entry into a permit space, the entrants and attendants will perform the duties outlined in these procedures and will return the permit or documentation to (insert job title of responsible person) upon the termination of entry.

Cranes and Derricks (Ref. 29 CFR 1926.1400–1442)

Note: The following program is an example of a written program and based on the referenced standard. The standard does not require a written program but as a b it has been put into writing in this manual.Please modify or delete content to these policies as deemed necessary. The standard should be referenced to ensure that all requirements are being met.

Safe Work Practices

- Comply with the manufacturer’s specifications and limitations for all cranes and derricks.

- Rated load capacities, recommended operating speeds, and special hazard warnings or instructions will be conspicuously posted on all equipment.

- Instructions or warnings will be visible from the operator’s station.

- Equipment will be inspected by a competent person before each use and during use, and all deficiencies corrected before further use.

- Accessible areas within the swing radius of the rear of the rotating superstructure will be properly barricaded to prevent employees from being struck or crushed by the crane.

- Except where electrical distribution and transmission lines have been de-energized and visibly grounded at point of work, or where insulating barriers not a part of or an attachment to the equipment or machinery have been erected to prevent physical contact with the lines, no part of a crane or its load will be operated within 10 feet (3 m) of a line rated 50 kilovolts (kV) or below; 10 feet (3 m) plus 0.4 inches (10.2 cm) for each kV over 50 kV for lines rated over 50 kV, or twice the length of the line insulator, but never less than 10 feet (3 m).

- An annual inspection of the hoisting machinery will be made by a competent person. Records must be kept of the dates and results of each inspection.

- All crawler, truck or locomotive cranes in use will meet the requirements as prescribed in the ANSI B30.5-1968, Safety Code for Crawler, Locomotive and Truck Cranes. (212) 642-4900.

- The use of a crane or derrick to hoist employees on a personnel platform is prohibited, except when the erection, use, and dismantling of conventional means of reaching the worksite—such as a personnel hoist, ladder, stairway, aerial lift, elevating work platform or scaffold—would be more hazardous or is not possible because of structural design or worksite conditions.

- Crane operators will be trained and certified on cranes before being allowed to operate any crane.

Diving (Ref. 29 CFR 1926.1076–1084)

Note: This program may be mandatory for your company. Please reference the scope and application of the referenced OSHA standard. This is an example program and may be modified to meet the company’s needs. The standard should be referenced to ensure that all requirements are being met.

Responsibilities

Divers are responsible for attending diving safety training and following the Safe Practices Manual. Employees designated as persons-in-charge (PICs) are also responsible for the activities of each dive to which they are assigned and for preparing a dive plan/report.

The company is responsible for the following:

- Appointing a PIC for each dive.

- Verifying that authorized divers, standby personnel, and designated PICs are trained.

- Retaining completed dive plans and reports.

- Assessing the effectiveness of the diving manual.

- Keeping list of authorized divers.

- Conducting audits for compliance with diving safety requirements.

- Assessing diving safety training requirements.

- Developing and maintaining records of diving safety training.

Diver Certification

Divers will have a valid certification issued by the National Association of Underwater Instructors (NAUI), the Professional Association of Diving Instructors (PADI) or equivalent certifying organization. Each diver will also be currently certified in both cardio-pulmonary resuscitation (CPR) and standard first aid.

Person-in-Charge (PIC)

The PIC is responsible for the activities of the diving operation and will be at the dive site throughout its duration.

Dive Plan/Report

The PIC for each diving operation will prepare a dive plan/report. A copy of the dive plan/report will be kept with the dive team for the duration of the dive.

Pre-Dive Procedures

The PIC will conduct a briefing of dive team members prior to each dive on:

- The dive plan/report.

- Objectives of the dive.

- Unusual hazards or conditions.

- Modifications to standard or emergency procedures.

- A predive inspection of all equipment and supplies is made.

Dive Procedures

Diving operations will be conducted with two certified, fully suited and ready-to-dive employees. We will use either the buddy system or the standby system. If both divers are needed in the water, a third person will be stationed at the point of entry to provide for standby duties.

Prior to dive:

- The PIC coordinates the diving operation and prepares the dive plan/report.

- Employees are informed of the tasks and the required safe diving procedures.

- EMS and the local fire department should be advised of the diving operation and location.

During the diving operation, the diver should be line-tended by the standby diver using an appropriate body harness that will facilitate rescue, if required.

After the dive:

- The dive plan/report is completed.

- Post-dive procedures are completed.

Post-Dive Procedures

At the end of each dive, the PIC will:

- Observe the condition of each diver for signs of illness or distress.

- Verify completion and distribution of the dive plan/report.

At the end of each dive, each diver will:

- Use showering facilities.

- Report any physical problems or adverse physiological effects including symptoms of decompression sickness.

Medical Emergencies

Medical emergencies occurring as part of a dive should be reported immediately to the PIC. If the injured person cannot be safely transported to the emergency room at a hospital, EMS will be dispatched to provide initial treatment.

Emergency Treatment—Divers should provide initial first aid until additional services arrive at the scene.

Emergency Evacuation

If an incident occurs that may jeopardize the health or safety of a diver working in the water, diving operations should be terminated immediately and the divers should leave the water.

Equipment

- Compressors used to recharge self-contained underwater breathing apparatus (scuba) tanks should be inspected and maintained in accordance with breathing air requirements for such compressors as specified by 29 CFR 1910.430.

- The diving equipment used should meet the requirements identified in 29 CFR 1910.430.

- Emergency equipment will be provided and maintained at the point of entry for each diving operation in progress.

- Divers are responsible for the care and maintenance of all diving equipment.

Training

All divers will receive initial and periodic training.

Recordkeeping

- Records of diving safety training will be maintained for the duration of the employee’s employment.

- Depth-time profile (1910.422) must be kept until the completion of the recording of the dive, or until the completion of the decompression procedure assessment where there has been an incident of decompression sickness.

- A current list of authorized divers.

- Completed dive plans/reports will be kept for a period of one year beyond the completion of the work. If there was an incident of decompression sickness, the record must be kept for five years (1910.423).

- Decompression procedure assessment evaluations must be kept for five years (1910.423).

- Medical records for dive team members will be maintained for the duration of employment plus 30 years (1910.1020). Records of hospitalizations must be kept for five years (1910.440).

- For equipment inspections and testing records (1910.430), the current entry/log or tag must be kept readily available.

Diving Operations Plan

| Diver’s Name | Diver’s Agency | Certification Level | Diver’s Duties | Equipment to Be Used |

Electrical Safety (Ref. 29 CFR 1926.400–417)

Note: The following program is an example of a written policy based on the referenced standard. The standard does not require it to be in writing, but as a best practice, it has been put into writing in this manual. Please modify or delete content to the policy as deemed appropriate for your worksite. The standard should be referenced to ensure that all requirements are being met.

We will provide ground-fault circuit interrupters (GFCIs) to protect employees from ground-fault hazards at our job sites. All 120-volt, single-phase, 15- and 20-ampere receptacles that are not part of the permanent wiring must be protected by GFCIs.

Safe Work Practices

- Light bulbs for general illumination will be protected from breakage

- Metal shell sockets must be grounded.

- Temporary lights will not be suspended by their cords unless they are so designed.

- Portable lighting used in wet or conducive locations, such as tanks or boilers, will be operated at no more than 12 volts or must be protected by GFCIs.

- Extension cords will be of the three-wire type.

- Extension cords and flexible cords used with temporary and portable lights will be designed for hard or extra hard usage (for example, types S, ST and SO).

- Worn or frayed electric cords or cables will not be used.

- Extension cords will not be fastened with staples, hung from nails, or suspended by wire.

- Workspaces, walkways, and similar locations will be kept clear of cords.

- Listed, labeled or certified equipment will be installed and used in accordance with instructions included in the listing, labeling or certification.

- In work areas where the exact location of underground electrical power lines is unknown, employees using jackhammers, bars or other hand tools that may contact the lines will use insulating gloves, aprons or other protective clothing that will provide equivalent electrical protection.

- Barriers or other means of guarding will be used by employees to ensure that the workspace for electrical equipment is not used as a passageway during periods when energized parts of the equipment are exposed.

- Flexible cords will have strain relief provided to prevent pull from being directly transmitted to joints or terminal screws.

- Equipment or circuits that are de-energized will be rendered inoperative and will have tags attached at all points where the equipment or circuits could be energized.

Emergency Response (Ref. 29 CFR 1926.35)

Note: The following program is an example of a written policy based on the referenced standard. The standard does not require it to be in writing, but as a best practice, it has been put into writing in this manual. Please modify or delete content to the policy as deemed appropriate for your worksite. The standard should be referenced to ensure that all requirements are being met.

Medical Emergency

- Protect yourself and other workers from further injury.

- Call for emergency medical services as needed.

- Meet medical responders and guide them to the location.

- Immediately report the injury and location to (insert title).

- Do not move injured workers before medical assistance arrives unless they are in danger of further injury.

- Preserve the area around the accident scene so an investigation can be conducted.

Fire or Explosion

- Immediately report the fire and location to (insert title).

- Call the fire department or emergency medical services as needed.

- Do not attempt to extinguish the fire unless you have been trained.

- Evacuate the work area and report to the designated assembly area upon hearing the evacuation signal.

- Do not leave the assembly area until authorized to do so.

Severe Weather

- Secure loose materials.

- All workers on scaffolds, ladders, cranes, aerial lifts, and roofs must seek shelter.

- If an evacuation signal is given, seek a designated shelter area.

Bomb Threat

- Immediately report the threat to (insert title).

- Evacuate the work area and report to the designated assembly area upon hearing the evacuation signal.

- Do not leave the assembly area until authorized to do so.

Chemical Spill or Release

- Evacuate to a safe distance and secure the area.

- Report the occurrence to (insert title).

- Evacuate the work area and report to the designated assembly area upon hearing the evacuation signal.

- Do not leave the assembly area until authorized to do so.

Structural Failure or Collapse

- Evacuate to a safe distance and secure the area.

- Report the occurrence to (insert title).

- Evacuate the work area and report to the designated assembly area upon hearing the evacuation signal.

- Do not leave the assembly area until authorized to do so.

Excavations and Trenching (Ref. 29 CFR 1926.651–652)

Note: The following program is an example of a written policy and based on the referenced standard. The standard does not require it to be in writing, but as a best practice, it has been put into writing in this manual. Please modify or delete content to the policy as deemed appropriate for your worksite. The standard should be referenced to ensure that all requirements are being met.

Safe Work Practices for Underground Installations

The estimated location of utility installations—such as sewer, telephone, fuel, electric, water lines, or any other underground installations that reasonably may be expected to be encountered during excavation work—will be determined prior to opening an excavation.

Utility companies or owners will be contacted within established or customary local response times, advised of the proposed work, and asked to establish the location of the utility underground installations prior to the start of actual excavation. When utility companies or owners cannot respond to a request to locate underground utility installations within 24 hours (unless a longer period is required by state or local law), or cannot establish the exact location of these installations, we will proceed with caution and will provide detection equipment or other acceptable means to locate utility installations.

When excavation operations approach the estimated location of underground installations, the exact location of the installations will be determined by safe and acceptable means. While the excavation is open, underground installations will be protected, supported, or removed to safeguard employees.

Each employee in an excavation will be protected from cave-ins by an adequate protective system except when excavations are made entirely in stable rock, or excavations are less than 5 feet (1.5 m) in depth and examination of the ground by the competent person provides no indication of a potential cave-in. Protective systems will have the capacity to resist, without failure, all loads that are intended or could reasonably be expected to be applied or transmitted to the system.

Employees will be protected from excavated or other materials or equipment that could pose hazards by falling or rolling into excavations. Protection will be provided by placing and keeping such materials or equipment at least 2 feet (0.6 m) from the edge of excavations, or by the use of retaining devices that are sufficient to prevent materials or equipment from falling or rolling into excavations, or by a combination of both if necessary.

Inspections

Daily inspections of excavations, the adjacent areas, and protective systems will be made by a competent person for evidence of a situation that could result in possible cave-ins, indications of failure of protective systems, hazardous atmospheres, or other hazardous conditions. An inspection will be conducted by the competent person prior to the start of work and as needed throughout the shift. Inspections will also be made after every rainstorm or other hazard-increasing occurrence.

Where a competent person finds evidence of a situation that could result in a possible cave-in, indications of failure of protective systems, hazardous atmospheres, or other hazardous conditions, exposed employees will be removed from the hazardous area until the necessary precautions have been taken to ensure their safety.

Trench and Excavation Access

A stairway, ladder, ramp, or other safe means of egress will be located in trench excavations that are 4 feet or more in-depth so as to require no more than 25 feet of lateral travel for employees.

Fall Protection (Ref. 29 CFR 1926.500–502)

Note: The following program is an example of a written policy based on the referenced standard. The standard does not require it to be in writing, but as a best practice, it has been put into writing in this manual. Please modify or delete content to the policy as deemed appropriate for your worksite. The standard should be referenced to ensure that all requirements are being met.

We will assess the worksite to determine if the walking/working surface on which employees are to work has the strength and structural integrity to safely support workers. Employees are not permitted to work on those surfaces until it has been determined that the surfaces have the requisite strength and structural integrity to support the workers.

Safe Work Practices

- Employees are to use 100 percent fall protection at all times.

- Each employee in a hoist area will be protected from falling 6 feet or more by guardrail systems or personal fall arrest systems. If guardrail systems (or chain gate or guardrail) or portions thereof must be removed to facilitate hoisting operations, as during the landing of materials, and a worker must lean through the access opening or out over the edge of the access opening to receive or guide equipment and materials, that employee will be protected by a personal fall arrest system.

- Covers or guardrail systems will be erected around holes (including skylights) that are more than 6 feet (1.8 m) above lower levels unless personal fall arrest systems are used by all exposed employees.

- Each employee at the edge of an excavation 6 feet deep (1.8 m) or more will be protected from falling by guardrail systems, fences, barricades or covers.

- Where walkways are provided to permit employees to cross over excavations, guardrails are required on the walkway if it is 6 feet (1.8 m) or more above the excavation.

- Each employee using ramps, runways, and other walkways will be protected from falling 6 feet (1.2 m) or more by guardrail systems.

- Each employee performing overhand bricklaying and related work 6 feet (1.8 m) or more above lower levels will be protected by guardrail systems, safety net systems,, or personal fall arrest systems or will work in a controlled access zone.

- All employees reaching more than 10 inches (25.4 cm) below the level of a walking/working surface on which they are working will be protected by a guardrail system, safety net system,, or personal fall arrest.

- On low-slope roofs,50 feet (15.2 m) or less in width, the use of a safety monitoring system without a warning line system is permitted.

- Each employee on a steep roof with unprotected sides and edges 6 feet (1.8 m) or more above lower levels will be protected by guardrail systems with toeboards, safety net systems, or personal fall arrest systems.

- Fall protection is not needed if an employee or employees are on a low slope roof (less than 4/12 pitch) for inspection/observation only.

Please note: Fall protection is required whenever an employee is above 6 feet on construction sites (except 10 feet on scaffolding and 15 feet during steel erection).

Types of Fall Protection Systems

- Articulating manlifts provided with a restraint system and full body harness to an anchor point below the waist (preferably at the floor level).

- Guardrails with toeboards.

- Personal fall arrest systems:

- Anchor points (rated at 5,000 pounds).

- Full body harness.

- Restraint line or lanyard.

- Shock-absorbing lanyard.

- Retractable lanyard.

- Rope grabs.

- Connectors (self-locking snap hooks).

- Engineered lifelines.

- Warning lines.

- Safety nets.

- Safety monitoring systems.

Fall Protection Guidelines

Engineering Controls

Engineering controls will be the first option for selection whenever possible (i.e., light bulb changing, telescoping arm, changing valve, relocating at ground level) or utilizing a contractor in extremely hazardous areas.

Guardrails

On all projects, only guardrails made from steel, wood, or wire rope will be acceptable. All guardrail systems will comply with OSHA standards (i.e., withstand 200 pounds of force, 42 inches high, mid rail, and toe board). These guardrails will be placed in the following areas if necessary or feasible based on job location or requirements:

- On all open-sided floors.

- Around all open excavations or pits.

- On leading edges of roofs or mezzanines.

Wall Openings

Wall openings from which there is a drop of more than 6 feet (1.8 m) and the bottom of the opening is less than 39 inches (1 m) above the working surface will be guarded.

Falling Objects

Employees will wear a hard hat when there are overhead hazards. Whenever possible, toeboards, screens, guardrail systems or a barricade will be placed in the area to keep objects from falling onto employees below.

Personal Fall Protection Systems (PFAS)

All employees on any project that will be required to wear a personal fall arrest or restraint system will follow these guidelines:

- A full-body harness will be used at all times.

- All personal fall arrest systems will be inspected before each use by the employee. Any deteriorated, bent, damaged or impacted, and components of harnesses showing excessive wear will be removed from service.

- Connectors will be inspected to ensure they are drop forged, pressed or formed steel or are made of equivalent materials and that they have a corrosion-resistant finish as well as that all surfaces and edges are smooth to prevent damage to interfacing parts of the system.

- Verify that D rings and snap hooks have a minimum tensile strength of 5,000 pounds and that the D rings and snap hooks are proof tested to a minimum tensile load of 3,600 pounds without cracking, breaking or taking permanent deformation.

- Only shock-absorbing lanyards or retractable lanyards are to be used so as to keep impact forces at a minimum on the body (fall arrest systems).

- Only nylon rope or nylon straps with locking snap hooks are to be used for restraints.

- All lanyards will have self-locking snap hooks.

Verify that unintentional disengagement of snap hooks is prevented by either of the following means:

- Snap hooks are a compatible size for the member to which they are connected.

- Locking-type snap hooks are used.

Verify that unless the snap hook is a locking type and is designed for the following connections, snap hooks are not engaged in the following manners:

- Directly to webbing, rope, or wire rope.

- To each other.

- To a D ring to which another snap hook or other connector is attached to a horizontal lifeline.

- To any object that is incompatibly shaped or dimensioned in relation to the snap hook such that unintentional disengagement could occur by the connected object being able to depress the snap hook keeper and release itself.

The following factors can affect total fall distance:

- Length of connecting means (i.e., lanyard length, use of carabineers, snap hooks).

- Position and height of anchorage relative to work platform/area (always keep above head whenever possible).

- Position of attachment and D-ring slide on the full body harness.

- Deployment of shock absorber (max 42 inches).

- Movement in a lifeline.

- The initial position of the worker before free fall occurs (i.e., sitting, standing).

Calculating Total Fall Distance

It is the total length of the shock-absorbing lanyard plus the height of the person plus the location distance of the D ring from the work surface or platform. Always allow a minimum of 6 feet of clearance above the ground, equipment, etc., at the end of the fall from the fall arrest point.

Engineered Lifeline

Lifeline systems must be designed and approved by an engineer or qualified person. Lifeline systems must be engineered to have appropriate anchorages, strength of line designed to hold X number of individuals connected to it, line strength to aid in the arrest of a fall, and durability to hold fallen employee(s) suspended until rescue can occur.

Warning Line System

All greater than 50 feet wide flat roof (i.e., roof with less than 4 in 12 slope) work that is performed 6 feet or further back from the edge of the roof can be completed by installing a warning line and using a safety monitor. If the roof is flat and less than 50 feet wide, a competent person safety monitor may be used.

Warning lines will consist of the following:

- Be erected 6 feet from the edge of the roof.

- Be constructed of stationary posts made of wood or metal.

- Wire or nylon rope and “Caution” tape will be strung from post to post and must be able to withstand 16 pounds of force.

- The entire perimeter of the roof where work is being performed will be guarded by the warning line.

If an employee must access an area within 6 feet of the roof for reasons other than exiting the roof via a ladder or fixed industrial ladder, another employee must monitor that individual and warn him or her of any dangers. If another employee is not available to act as a safety monitor, the employee must don a full-body harness and attach a fall restraint lanyard to an anchor point to prevent reaching the edge of the roof.

Inspection of Fall Protection Systems

The following criteria will be utilized to maintain all equipment in good working condition.

Full Body Harness

Inspect before each use:

- Closely examine all of the nylon webbings to ensure there are no burn marks, which could weaken the material.

- Verify there are no torn, frayed, broken fibers, pulled stitches or frayed edges anywhere on the harness.

- Examine D ring for excessive wear, pits, deterioration or cracks.

- Verify that buckles are not deformed or cracked and will operate correctly.

- Check to see that all grommets (if present) are secure and not deformed from abuse or a fall.

- Harness should never have additional punched holes.

- All rivets should be tight, not deformed.

- Check tongue/straps for excessive wear from repeated buckling.

A competent person will conduct an annual inspection of all harnesses. The documentation will be provided to (insert job title of responsible person) and maintained for (entered length of time to keep a record).

Storage will consist of hanging in an enclosed cabinet to protect from damage.

All harnesses that are involved in a fall will be removed from/tagged out of service immediately.

Lanyards/Shock Absorbing Lanyard

Before each use, the employee must:

- Check lanyard material for cuts, burns, abrasions, kinks, knots, broken stitches, and excessive wear.

- Inspect the snap hooks for hook, locks,, and eye distortion.

- Check the carabineer for excessive wear, distortion and lock operation.

- Ensure that all locking mechanisms seat and lock properly.

- Once locked, locking mechanism should prevent hook from opening.

- Visually inspect shock absorber for any signs of damage, paying close attention to where the shock absorber attaches to the lanyard.

- Verify that points where the lanyard attaches to the snap hooks are free of detects.

A competent person will conduct an annual inspection of all lanyards. The inspection documentation will be provided to (insert job title of responsible person) and maintained for (insert length of time to keep record).

Storage will consist of hanging in an enclosed cabinet to protect from damage.

All lanyards that are involved in a fall will be destroyed.

Snap Hooks

Before each use, the employee will:

- Inspect snap hook for any hook and eye distortions.

- Verify there are no cracks, pitted surfaces and eye distortions.

- The keeper latch should not be bent, distorted or obstructed.

- Verify that the keeper latch seats into the nose without binding.

- Verify that the keeper spring securely closes the keeper latch.

- Test the locking mechanism to verify that the keeper latch locks properly.

A competent person will conduct an annual inspection of all snaphooks. The inspection documentation will be provided to (insert job title of responsible person) and maintained for (insert length of time to keep record).

All snap hooks involved in a fall will be removed from/tagged out of service.

Self-Retracting Lanyards

Before each use, the employee will:

- Visually inspect the body to ensure there is no physical damage.

- Make sure all back nuts or rivets are tight.

- Make sure the entire length of the nylon strap is free of any cuts, burns, abrasions, kinks, knots, broken stitches, and excessive wear and retracts freely.

- Test the unit by pulling sharply on the lanyard to verify that the locking mechanism is operating correctly.

- If manufacturer requires, make certain the retractable lanyard is returned to the manufacturer for scheduled annual inspections.

A competent person will conduct a monthly inspection of all self-retracting lanyards. The inspection documentation will be provided to (insert job title of responsible person) and maintained for (insert length of time to keep record). Additionally, the lanyard will be inspected for proper function after every fall.

Tie-off Adaptors/Anchorages

- Inspect for integrity and attachment to solid surface.

- Annual inspection of all tie-offs and anchorages by a competent person with documentation.

- All tie-offs and anchorages will be destroyed and replaced after a fall.

Articulating Manlift

- Inspect before each use.

- Inspect/service per manufacturer’s guidelines. Forklifts, scissors lifts and safety nets will be inspected at the beginning of each shift in use. Structural integrity of forklift basket will be checked per same schedule.

- Annual inspection of forklift basket will be completed by a competent person with documentation maintained.

Horizontal Lifelines

- Inspect before each use for structural integrity of line and anchors.

- Annual inspection by a competent person.

Guardrails

- Temporary systems—Daily visual inspection will be completed by a competent person.

- Temporary systems—Weekly, a complete structural inspection will be completed by a competent person.

- Permanent systems—Annual structural inspection will be completed by a competent person with future frequency of inspection defined based on conditions/controls present.

Storage and Maintenance of Fall Protection Equipment (Best Practice)

- Never store the personal fall arrest equipment in the bottom of a toolbox, on the ground or outside exposed to the elements (i.e., sun, rain, snow).

- Hang equipment in a cool dry location in a manner that retains its shape.

- Always follow manufacturer’s recommendations for inspection.

- Clean with a mild, nonabrasive soap and hang to dry.

- Never force dry or use strong detergents in cleaning.

- Never store equipment near excessive heat, chemicals, moisture or sunlight.

- Never store in an area with exposures to fumes or corrosives elements.

- Avoid dirt and build-up on equipment.

- Never use this equipment for any purpose other than personal fall arrest.

- Once exposed to a fall, remove equipment from service immediately.

Training

The company will provide a fall prevention training program for each employee who might be exposed to fall hazards. The training program will include recognition of the hazards of falling and procedures to follow to minimize these hazards. Training materials will be reviewed to verify that each employee has been trained, as necessary, by a competent person qualified in the following areas:

- Nature of fall hazards in the work area.

- Correct procedures for erecting, maintaining, disassembling and inspecting the fall protection systems to be used.

- Use and operation of guardrail systems, personal fall arrest systems, safety net systems, warning line systems, safety monitoring systems, controlled access zones (CAZs) and other protection to be used.

- Role of each employee in the safety monitoring system when this system is used.

- The limitations on the use of mechanical equipment during the performance of roofing work on low-sloped roofs.

- Correct procedures for the handling and storage of equipment and materials and the erection of overhead protection.

- Role of employees in fall protection plans.

- Requirements contained in 29 CFR 1926, Subpart M.

- Understanding and following all components of this fall protection program.

The company will maintain a written certification record for employee training. The record must contain the following information:

- Name or other identity of the employee trained.

- Date(s) of the training.

- Signature of the person who conducted the training or the signature of a company official.

When the supervisor has reason to believe that any affected employee who has already been trained does not have the understanding and skill required, the supervisor will retrain that employee. Retraining is required at least in the following circumstances:

- Changes in the workplace render previous training obsolete.

- Changes in the types of fall protection systems or equipment to be used render previous training obsolete.

- Inadequacies in an affected employee’s knowledge or use of fall protection systems or equipment indicate that the employee has not retained the requisite understanding or skill.

Enforcement (Best Practice)

- Subject to discipline.

- Documentation of any violations will be kept in the staff member’s personnel file.

- Any employee not following the fall protection program or a portion of this procedure will be subject to disciplinary action.

Rescue Procedures

In the event of a fall, the following people will be notified as soon as possible to initiate rescue:

- Rescue personnel on-site.

- Supervisor/management.

- Fire department or emergency medical services if necessary.

At the beginning of any work activity where fall protection is required, rescue plans must be identified and discussed with all employees in case of a fall. The supervisor willdevelop the rescue plans.

All employees involved in a fall arrest or fall will be sent for a medical evaluation to determine extent of injuries, if any.

Program Evaluation

This fall protection program will be evaluated periodically to determine effectiveness. The following criteria will be used to evaluate its performance:

- Accident reports, number of accidents.

- Management/staff compliance with program components.

- Periodic on-site audits.

- Staff feedback, interviews.

Contractors

All outside contractors working in or on the premises will be required to follow the guidelines set forth in this fall protection program when the contractor and employees are exposed to fall hazards. Contractors in the pre-job meeting will be informed of these requirements as well as the on-site construction rules that apply.

Fire Protection (Ref: 29 CFR 1926.150–152)

Note: The following program is an example of a written policy based on the referenced standard. The standard does not require it to be in writing, but as a best practice, it has been put into writing in this manual. Please modify or delete content to the policy as deemed appropriate for your worksite. The standard should be referenced to ensure that all requirements are being met.

The primary goal of this fire protection program is to reduce or eliminate fires in the worksite by heightening the fire safety awareness of all employees. Our program will be followed throughout all phases of the construction and demolition work involved.

Classification

Fires are classified into four groups according to sources of fuel: Class A, B, C, and D based on the type of fuel source. Table 1 below describes the classifications of fire that can be used in making a hazard assessment.

Table 1

| Class A | Ordinary combustible materials such as paper, wood, cloth, and some rubber and plastic materials. |

| Class B | Flammable or combustible liquids, flammable gases, greases, and similar materials, and some rubber and plastic materials. |

| Class C | Energized electrical equipment and power supply circuits and related materials. |

| Class D | Combustible metals such as magnesium, titanium, zirconium, sodium, lithium, and potassium. |

Fire Fighting Equipment

A fire extinguisher rated not less than 2A (acceptable substitutes are a ½-inch diameter garden-type hose not to exceed 100 feet capable of discharging a minimum of 5 gallons per minute or a 55-gallon drum of water with two fire pails), will be provided for every 3,000 square feet (270 square m) of the protected building area, or major fraction thereof. Travel distance from any point of the protected area to the nearest fire extinguisher must not exceed 100 feet (30.5 m).

Fire extinguishers will be conspicuously located, inspected monthly, and placed within the immediate area of any welding/cutting operation or a flammable liquid storage area. Any expired fire extinguisher will be reported to (insert title).

Access to fire hydrants will be maintained at all times. Access to buildings and other structures will be maintained at all times.

Safe Work Practices

- Combustible refuse from construction operations will not be burned or dumped anywhere on the worksite. Such refuse will be removed at frequent intervals.