In an effort to reduce the high number of injuries and deaths that occur on construction sites, the Occupational Safety and Health Administration, OSHA, has identified the four most common causes of injuries and fatalities in construction. Known as the “Fatal Four” or the “Focus Four,” these hazards include struck-by hazards, caught-between hazards, fall hazards, and electrocution hazards. “Struck-by” injuries occur when any type of object or piece of equipment makes forcible contact with an employee. Struck-by hazards are divided into the following groups: flying objects, falling objects, swinging objects, and rolling objects. This article discusses specific hazards from these four groups and the safe work practices workers must follow to protect themselves from these threats.

Topics include safety tips for preventing each group of struck-by injuries, personal protective equipment, safe tool use and preventing vehicle incidents.

After reading, you will be able to explain the following:

- Which common flying object hazards can be found on a construction site and safety tips for avoiding them.

- What are the common sources of falling object hazards are and how to prevent falling object injuries.

- How swinging object hazards are created and how to protect against them.

- How rolling object incidents typically occur and how they can be prevented.

BACKGROUND

- As a construction worker, you already know that the Jobsite can be dangerous. In fact, over 5,000 construction workers are killed and over 150,000 are injured each year.

- In an effort to reduce the high number of construction-related incidents, the Occupational Safety and Health Administration, OSHA, has identified the four most common causes of injuries and fatalities in construction.

- Known as the “Fatal Four” or the “Focus Four,” these hazards include struck-by hazards, caught-between hazards, fall hazards, and electrocution hazards.

STRUCK-BY HAZARDS: One of the Fatal Four

- “Struck-by” injuries occur when any type of object or piece of equipment makes forcible contact with an employee.

- If not fatal, these incidents often result in broken bones, cuts, bruises, blunt force trauma, and other injuries to the feet, head, or body.

- Struck-by hazards are divided into the following groups: flying objects, falling objects, swinging objects, and rolling objects.

FLYING OBJECT HAZARDS

- Hazards from flying objects exist when something has been thrown or propelled across the worksite. This can happen accidentally or on purpose.

- Some common activities that may lead to flying object injuries include using a nail gun or other pneumatic or powder-actuated tools. The projectiles ejected from these tools can be extremely hazardous.

- Similarly, using compressed air for cleaning can also cause flying object hazards.

- Another way that flying object hazards occur is when cracked or splintered hand tools come apart while in use and send pieces flying through the air.

- Of course, any type of horseplay or intentionally throwing objects at or near others is extremely dangerous and has no place on a Jobsite.

- Any item under pressure or under a force that suddenly breaks free can become a flying object. Frozen bolts, pressurized hoses, tie-down straps and similar objects can suddenly become a hazard.

- Finally, the general activities performed on a construction site can result in flying objects that can injure or kill nearby workers.

- For instance, using machines such as jackhammers, pavement saws, welding tools, grinders, and other specialty equipment can send materials flying through the air and strike other workers.

A READING FROM THE OSHA FILES

Construction Worker Testimonial:

“We had a carpenter apprentice onsite that day. He died after being struck in the head by a nail that was fired from a nail gun. The guy using the gun was trying to anchor a plywood form for a concrete wall. The nail went straight through the hollow wall. It ended up shooting almost 30 feet across before hitting the carpenter in the head.”

- According to OSHA’s records, the nail gun operator had never received training in the proper use of the tool and none of the employees in the area were wearing any type of personal protective equipment. Had these simple precautions been taken, that worker may be alive today.

SAFETY TIPS FOR PREVENTING FLYING OBJECT INJURIES

- When cleaning with compressed air, reduce the pressure to 30 PSI or less by using an approved safety nozzle.

- Inspect hand tools before use and do not use tools with loose, cracked, or splintered handles.

- Also, do not use impact or striking tools if they have a mushroomed head.

- Operators of pneumatic or powder-actuated tools must be trained to safely use the tool.

- Never point the tool at anyone and do not fire the tool into any surface where it could pass through and hit someone on the other side.

- Only load a powder-actuated tool immediately prior to use and never leave a loaded tool unattended.

- When using saws, drills, grinders, etc., make sure you have checked the area around you for the presence of other workers.

- Set up signage or barriers to keep others out of the line of fire.

PERSONAL PROTECTIVE EQUIPMENT

- Personal protective equipment, or PPE, provides critical protection from struck-by hazards.

- Hardhats, safety glasses, and steel-toed boots provide protection for our heads, eyes, and feet from falling, flying, swinging, and rolling objects.

- This is why hard hats, safety glasses, and steel-toed boots are mandatory on many construction job sites.

- Certain job tasks such as grinding will also require a face shield for additional protection from flying objects.

- Always wear PPE when required and if you are unsure, ask your supervisor.

FALLING OBJECT HAZARDS

- When objects are dropped or thrown from above, they are considered “falling object hazards.“

- For instance, on many construction sites, there are employees working from multiple levels. If one employee is elevated on a platform, ladder, or boom lift and accidentally drops a tool or piece of material, anyone working below could be injured or killed.

- Tools or objects falling from scaffolding or unprotected edges is another common source of falling object hazards.

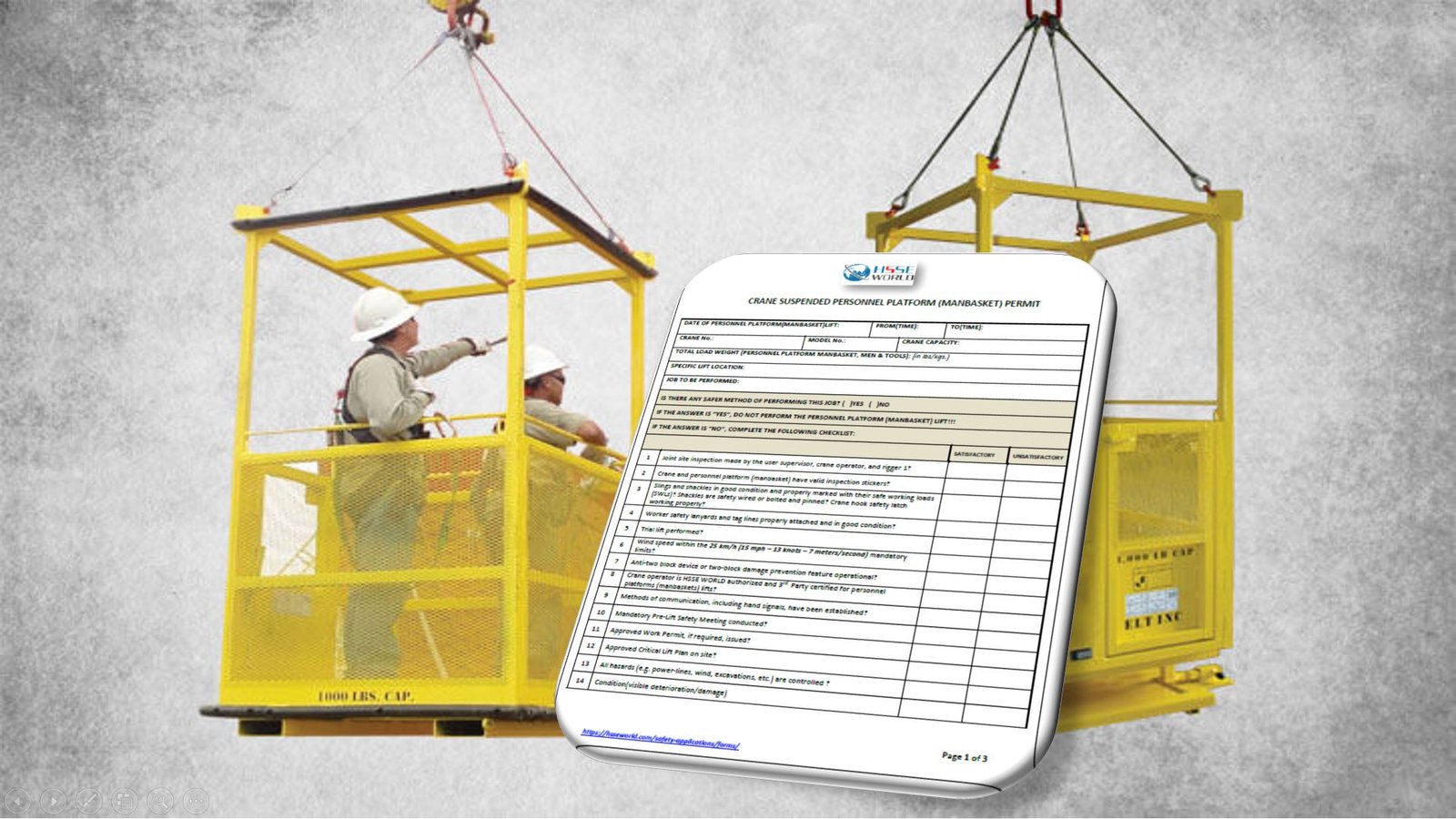

- Also, when a hoist or lifting device fails and its load suddenly drops to the ground, a very serious hazard is created.

( know the dropped-object-consequence-calculator/)

SAFETY TIPS FOR PREVENTING FALLING OBJECT INJURIES

- To prevent falling objects from striking workers below a scaffold, either the area around the scaffold must be barricaded to prevent entry or toe boards must be installed along the edge of the scaffold’s platforms to prevent falling objects.

- If tools or supplies are stacked higher than the top edge of a toe board, then screens or debris netting must be used to keep them from falling.

- Workers on, around or below scaffolds must wear hardhats at all times.

- Never walk or work underneath or next to a suspended load; always keep well clear.

- Also, don’t stand under a ladder while someone is working above and only climb ladders one person at a time.

- The use of tool tethering devices is a great way to prevent tools from falling while climbing or working.

- Always make sure slings and lifting devices are in good condition and only trained and authorized persons should perform rigging and hoisting operations.

- Don’t stack stored materials too high and secure items that may shift or move with tie-down straps or by other means.

- Do not stack or store items near any unprotected edge or floor opening.

SWINGING OBJECT HAZARDS

- When materials are lifted, hoisted, and transported through the air, they have the potential to become a “swinging object” and come into contact with workers.

- Windy conditions often increase the likelihood that a load will swing.

- Additionally, equipment like backhoes, cranes and forklifts may also become swinging object hazards as they move about the worksite or pivot during the course of their work.

- An often-overlooked cause of swinging object injuries are items that are hinged, such as equipment covers, vehicle hoods, heavy doors or dumpster lids.

SAFETY TIPS FOR PREVENTING SWINGING OBJECT INJURIES

- To protect yourself from swinging object hazards, always stay well clear of mobile equipment and vehicles that are operating on construction sites.

- Make note of the swing radius of any equipment operating nearby and stay out of this hazardous area.

- Crane and hoist operators should barricade or mark the swing radius of any load they are carrying so other workers can stay clear.

- Construction workers should wear high visibility clothing in order to be easily seen by equipment and vehicle operators.

- When operating any hinged item, keep hands and other body parts well clear of the pinch points.

- Keep a lookout for others before suddenly swinging open any type of door or dropping a hinged cover.

- Secure or brace any type of hinged object if you must place yourself into the line of fire.

ROLLING OBJECT HAZARDS

- Rolling object hazards exist when objects start rolling, moving or sliding unexpectedly.

- This type of incident commonly occurs when items are stored on a slope without being secured, stacked in an unstable manner or when objects that had been secured become unstable when the securing mechanism is removed.

- Common construction materials that could roll include portable tanks, cylinders, and pipes. Moving vehicles are also considered a rolling object hazard.

SAFETY TIPS FOR PREVENTING ROLLING OBJECT INJURIES

- To prevent rolling object injuries, make sure you are following the proper unloading procedures and make sure you are standing out of the line of fire.

- Always secure pipes and other construction materials that can roll. Never store tanks or cylinders on their side. Keep them upright so they cannot roll.

- When vehicles are parked on a grade, consider using wheel chocks in addition to the parking brakes to prevent vehicles from unexpectedly rolling, especially if you plan to crawl underneath.

- To prevent vehicle incidents, workers should always wear high visibility clothing and drivers should drive slowly and cautiously at all times.

- Workers should never stand directly behind moving equipment where the driver cannot see them and drivers should always check behind their vehicle before backing up.

- “Back-over” incidents are a leading cause of struck-by fatalities that involve moving vehicles.

SUMMARY

The struck-by hazards we have discussed: flying objects, falling objects, swinging objects, and rolling objects are part of OSHA’s Fatal Four construction hazards that make up nearly 60 percent of all construction-related injuries and fatalities.

Don’t become one of these statistics or stories. Stay alert on the job site and follow safe work practices to protect yourself from the struck-by hazards found on a construction job site.

64 comments