Aerial lifts are often used in shipyards and boatyards when the erection of staging is impractical. These booms supported personnel platforms and bucket trucks (i.e., cherry pickers) may cause worker injuries or deaths. Boom failure, tip-over, falls and ejection may occur if the equipment is not properly used. Employers must take measures to ensure a safe work environment by providing:

- Safe and adequately maintained equipment

- Proper supervision and training

- Fall protection

- Prompt rescue in the event of a fall

You Can Read the Aerial Lift Fall Protection over water in shipyards Quick Card by flipping the book below :

Also Read: OSHA Quick Card: Reducing Falls During Residential Construction: working in Attics

Safe Work Practices

- Always tie-off.

- Wear a body harness with a lanyard attached to an adequate anchorage point.

- Never move the lift with workers elevated.

- Train operators to safely operate the equipment.

- Maintain and operate equipment in accord with the manufacturer’s instructions.

- Ensure that equipment controls are properly marked.

- Never override safety devices. Overriding may lead to accidental or inadvertent movement of the basket or lift.

- When a lift is on a barge, be aware of the list, trim, and lash down points.

- Place stops to prevent driving off when a lift is near open edges and capable of movement.

- Know the swing radius to ensure that the aerial lift will not hit nearby structures as it moves.

- When elevated, never get between structures and the lift. MOVEMENT COULD CRUSH THE WORKER.

- To prevent tip-overs, it is important to:

- set brakes

- use wheel chocks

- check tire pressure

- extend outriggers

- ensure lift is level (front/back/sides)

- never operate in high winds

- never operate under power lines

- A Personal Flotation Device (PFD) alone will not help if a worker falls from heights of more than 40 feet to the water, or onto objects below (camels, floats, punts, fenders, or large floating objects). Always tie-off.

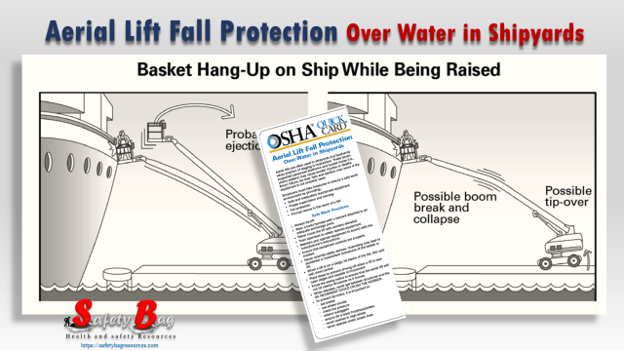

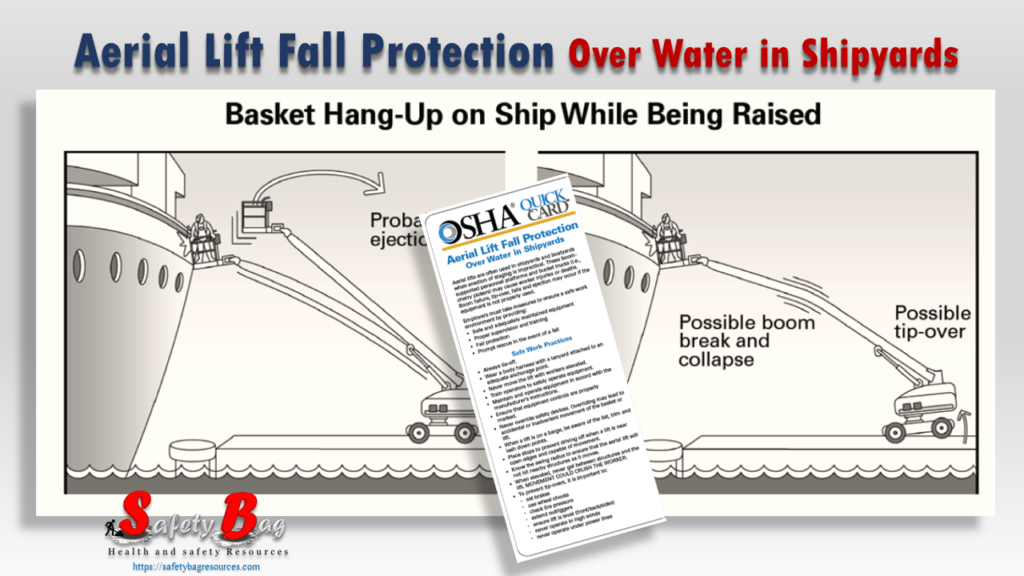

- If a lift gets caught on an object or lines, it may cause an ejection when it comes loose. Never lift, push or move objects with an aerial lift; this action may cause collapse, tip-over, or ejection.

- Never exceed load capacity with the combined weight of the worker, tools, and light materials. The extra weight may cause a collapse or tip-over. The lift capacity is reduced when the lift is not level tire pressure is low, or the outriggers are not fully extended. These conditions may cause a tip-over.

- Half of all fatal falls from aerial lifts occur when workers are not tied off. One worker was ejected 80 feet from an aerial lift.

- Improper set-up, operation, or exceeding weight capacity account for twice as many aerial lift fatal falls as mechanical failure.

Also Read: Tool Box Talk: Aerial Lift Safety

Download The Quick Card

OSHA Quick Cards: Aerial Lift Fall Protection over water in shipyards

More Downloads

- Model High Hazard Safety Program

- Books: OSHA-Hazard communication for small Entity

- OSHA Programs: A Guide to Cranes and Derricks

- Books: OSHA-Permit Required Confined Spaces

- OSHA: Underground Construction (Tunneling)

- OSHA Recommended Practice of Health and Safety programs in construction

- Books: OSHA-Is it Safe to Enter Confined Space?

- CAL/OSHA Scaffold Guide for safe use of supported Scaffolds

- Books: CAL/OSHA Pocket Guide for Construction Industry

- OSHA Programs: Aerial Lifts Safety Program-UK University

- Programs: Stairways and Ladders A Guide to OSHA Rules

- OSHA Inspection Checklist 8-Pages