Some of the most common construction and manufacturing jobs create high levels of dust. These jobs often involve the use of power tools like cut-off saws, grinders, polishers, breakers, and sanders.

As an Employer, you have a duty to eliminate risks. If this is not reasonably practicable, use the hierarchy of controls to minimize the risk of dust exposure to workers.

in this article, the guidance advises employers on how to choose, use and maintain an on-tool extraction system to control dust.

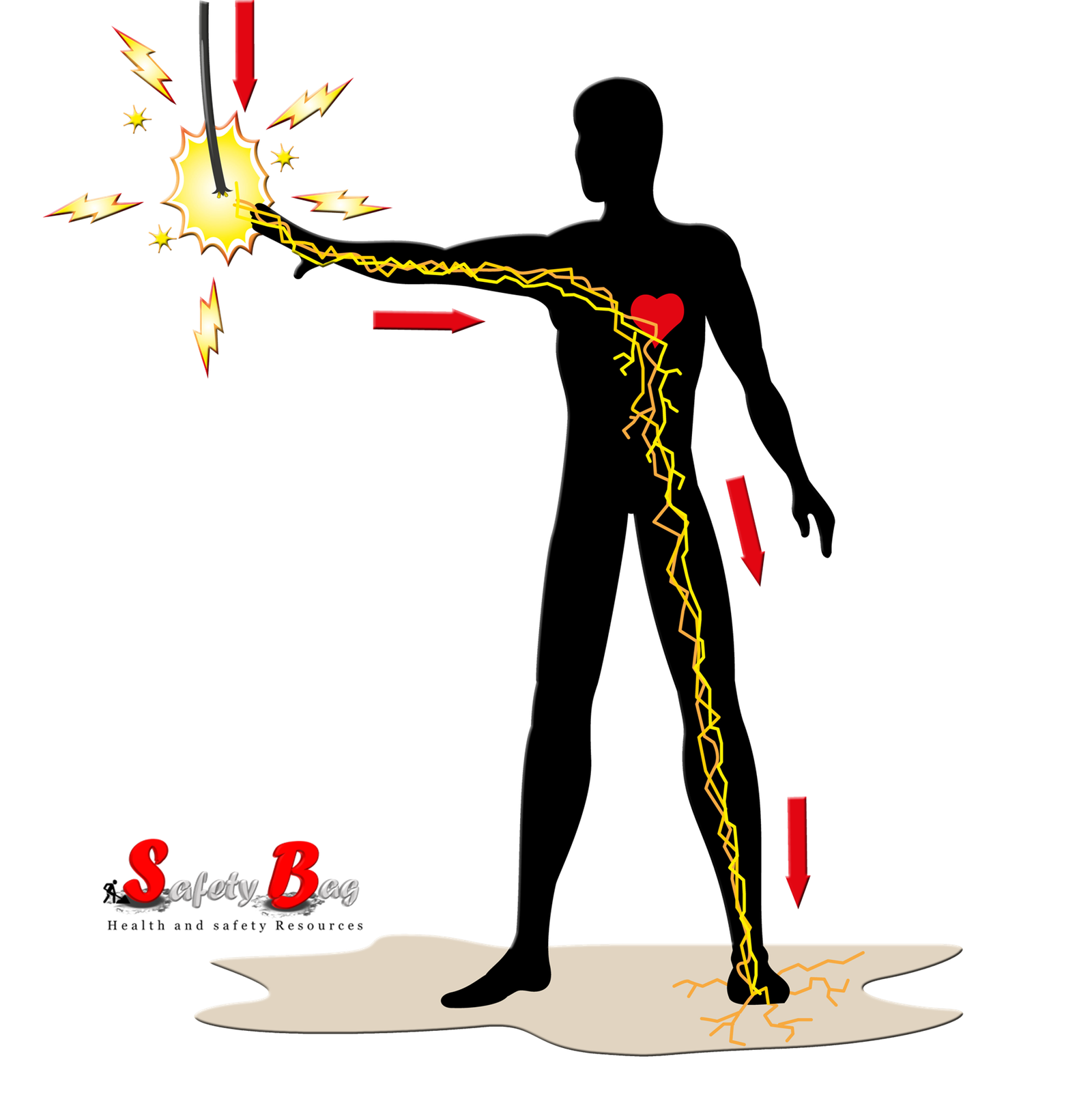

Risks presented by breathing in dust

Regularly breathing in dust can cause diseases like:

- lung cancer

- asthma

- chronic obstructive pulmonary disease (COPD, including emphysema and other breathing difficulties)

- silicosis (including accelerated and acute silicosis).

Choosing an on-tool extraction system

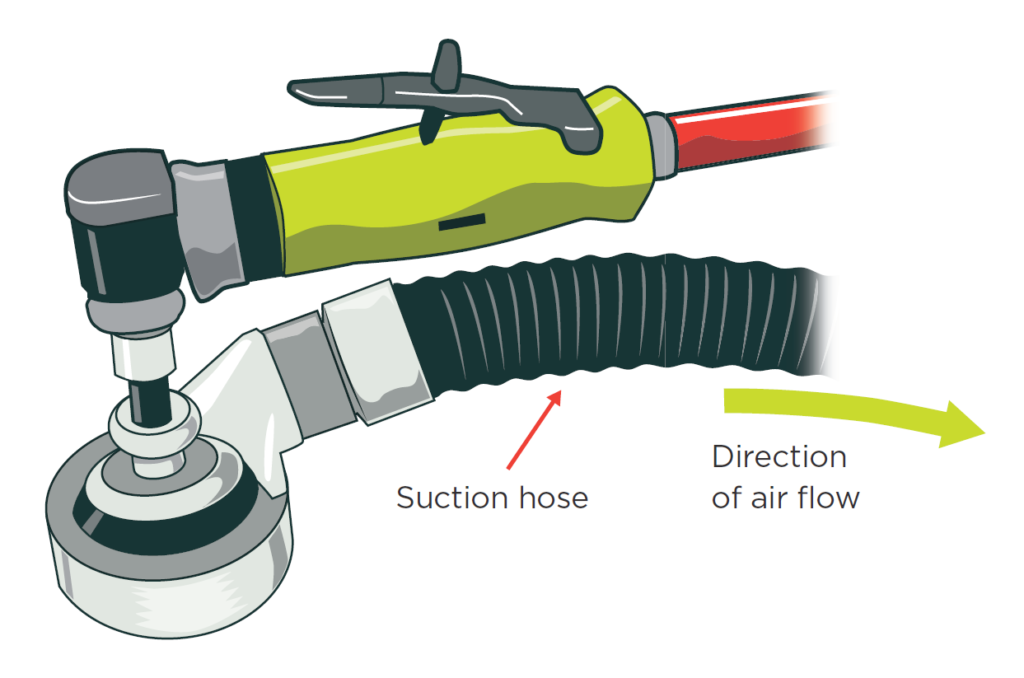

On-tool extraction is a type of local exhaust ventilation (LEV) system which is fitted directly onto the tool.

The system has several parts:

- the tool

- captor hood

- extraction unit, and

- hoses.

Each part is critical to the system’s effectiveness and level of dust control.

Complete on-tool extraction systems are available but some parts (especially extraction units) can be used with other tool makes and models.

For effective dust control, it’s important to choose parts that are compatible. Involve workers in selecting a system that’s right for the task.

Tools and accessories

Limit the amount of dust created by choosing appropriate tools and accessories. Choose sanding blocks/pads or grinding discs with enough holes to allow dust to be extracted through them.

Captor hood

The hood captures the dust as it’s produced and is the most important part of the LEV system. It’s often manufactured as part of the power tool but can also be retrofitted to existing equipment.

HOW TO CHOOSE THE RIGHT ONE

Poor design or damage to the hood will significantly affect dust control. Check that the hood:

- is designed for the tool and the task (seek guidance from the manufacturer or supplier)

- sits as close as possible to the work surface when in use, as dust will escape through any gaps

- is easy to use and doesn’t interfere with the work unnecessarily.

Extraction unit

The extraction unit is like an industrial vacuum. It removes dust from the captor hood, filters it, and collects it for safe disposal. Selecting the right extraction unit is key to successfully controlling dust.

HOW TO CHOOSE THE RIGHT ONE

Extraction units can be used interchangeably on some tools but the unit must be suitable for the tool and the task.

- The extraction unit should be suitable for the toxicity level and hazardous nature of the dust being extracted, as well as its size and type. Manufacturers of construction material can advise whether the dust produced by their products is classified as L (Low), M (Medium), H (High) class or non-hazardous.

- L class – dust representing a low risk

- M class – dust representing medium risk

- H class – dust representing high risk.

- Extraction units that conform to these classifications provide effective and certified extraction and containment of hazardous dust. They have special labels, operators’ manuals and, where applicable, low-airflow alarms and additional features for dust containment and disposal.

- FOR SILICA DUST: Use an H-class vacuum cleaner in accordance with Standard AS/NZS 60335.2.69. This includes when working at someone’s home (eg to fit a bench). Workers should not use a household vacuum cleaner to remove dust.

- Check that the extraction unit creates and maintains enough air suction to cope with the amount of dust created (manufacturers and suppliers can advise) – it needs to remove the dust as fast as it’s created.

- Lots of fine dust can quickly clog filters. Choose a unit with pre-filters, built-in ‘back-flushing’ filter cleaning mechanisms, or similar devices.

- Ensure the unit is emptied regularly and safely. See ‘During use’ below for more information.

- Check that the unit has enough waste capacity for the task.

( Read more about Silica Dust and Silicosis)

Hoses

Hoses connect the captor hood to the extraction unit.

HOW TO CHOOSE THE RIGHT ONE

Check that the hose:

- is the right construction, diameter and length for the work and the extraction unit

- fits securely to the hood and the extraction unit.

Using an on-tool extraction system

Providing the right equipment isn’t enough to control dust risks. The equipment must also be operated correctly and be properly maintained. Pay particular attention to each stage as follows:

Before use

PROVIDE TRAINING FOR WORKERS

Workers must have the right information, training, instruction, or supervision before using on-tool extraction. This includes information about:

- selecting the right on-tool extraction system

- pre-use checks

- ongoing maintenance

- how to use the system correctly

- other controls that may be needed (eg respiratory protective equipment and how to use/fit it properly)

- common faults, how to spot them, and the action to take

- what to do if there’s a problem.

During use

FOLLOWING OPERATING INSTRUCTIONS

Make sure the extraction unit is used in the right way:

- Before work starts, check the unit is undamaged and in good working order.

- Ensure sufficient consumables are available including filters, filter bags and disposal bags.

- Ensure workers follow the agreed methods of work and the manufacturer’s instructions.

- Ensure the captor hood is as close as possible to the work surface.

- Ensure the tubing is securely connected to the captor hood and extraction unit. Use an adaptor if needed. Do not use tape.

- The unit should be emptied regularly:

- use the correct disposable waste bags

- bags should be sealed and placed in the correct waste container

- if bags are designed for single use, do not empty them to recycle them.

- If the unit has a refillable container (instead of using bags), make sure to control your exposure to the dust when emptying it.

- Clean the unit regularly. Wipe it down daily. Do not use compressed air to clean the unit.

- Do not let dust build up on working parts.

Maintaining an on-tool extraction system

Regular checks/maintenance

Ensure that the system works properly every time. It is good practice to carry out regular maintenance checks at least once a week and record the results. You may have to do checks more frequently if there’s a high risk of the equipment being damaged.

Focus on:

- damage to parts such as the hood or ducting. Repair or replace damaged parts straight away

- maintaining the extraction unit’s airflow:

- follow manufacturer’s instructions

- check that the airflow indicator and any built-in cleaning mechanisms work properly

- replace filters when needed.

- replacing worn cutting discs.

Inspection and testing

Equipment needs proper servicing and testing to ensure it remains effective. For more information, contact the manufacturer or supplier, or ventilation engineers or occupational hygienists, if you’re unsure.

Cordless tools

The general principles of the above standards also apply to cordless tools with integrated filtered extraction devices. However, these units don’t fall under the L, M, or H classification system, so their suitability should be checked with the manufacturer before using them to extract dust.

( Read more about Detecting, Sampling, and Measuring Silica on Your Job Site )

118 thoughts on “How to control the Dust-On Tool Extraction”