Wearing a Seatbelt reduces the chances of you being injured in a vehicle or mobile heavy equipment accident. We recommend workers wear seatbelts when using vehicles or mobile Heavy equipment for work.

This article is a guide for workers about how to use a Seat belt including:

- When should seat belts be worn

- What vehicles and Mobile Heavy Equipment should have seat belts

- The business may monitor your seat belt use

- The business should talk with you about seat belt safety

- If you find your seat belt uncomfortable or hard to use, tell your manager or health and safety representative

- Your seat belt needs to be in good working order to keep you safe

When should seat belts be worn

Workers should wear seat belts whenever they are using a vehicle or mobile Heavy Equipment for work, and there is a seat belt available.

For example:

- on public roads, private roads, and off-road terrain

- outdoors and indoors at work sites/yards/ construction sites/depots/warehouses/farms

- when travelling to or from a job

- every journey no matter how short

- when travelling as a passenger.

What vehicles and mobile Heavy Equipment should have seat belts

Most modern vehicles and mobile Heavy Equipment should have seat belts installed.

For example:

- cars, vans, utility vehicles

- trucks (all sizes, types)

- forklifts

- heavy machinery (graders, bulldozers, excavators)

- tractors and other agricultural vehicles

- side-by-sides

- all vehicles and mobile Heavy Equipment with roll over or tip over protective structures (ROPS and TOPS) fitted.

If you have vehicles or mobile Heavy Equipment that have never had a seat belt installed, you should investigate if it is reasonably practicable to safely retrofit a seat belt. A qualified engineer should be able to advise you if it is possible ( Machines Access Control Inspection Checklists)

Promote and monitor seat belt use

You should promote and monitor the use of seat belts by your workers. There are many ways you can promote and monitor seat belt use. For example:

- create a workplace culture that promotes wearing seat belts, encourage workers to look out for each other by reminding each other if they have forgotten to put one on

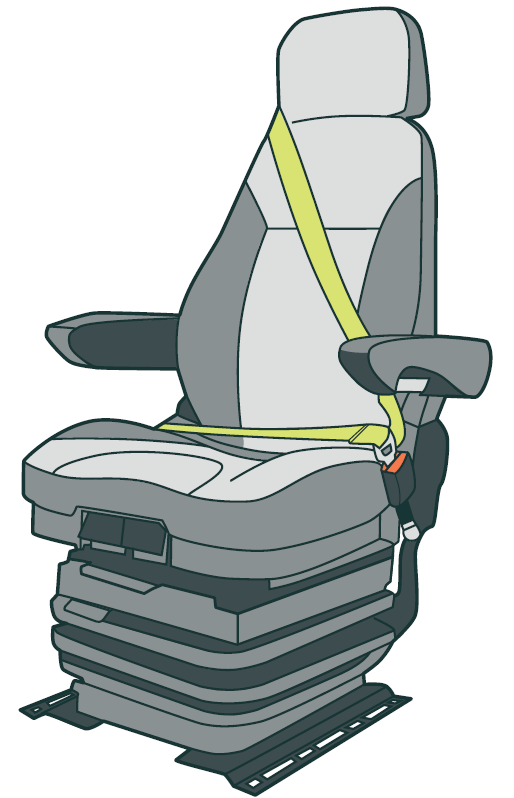

- use brightly coloured seat belts, so it is easier to see when a seat belt is being worn (see Figure 1)

- use seat belt systems that are interlocked with the vehicle or mobile Heavy Equipment’s ignition so workers cannot operate the vehicle or mobile Heavy Equipment without the seat belt being buckled

- install semi-rigid buckles that sit up from the driver’s seat – getting in the way of the worker until they buckle them This also makes it harder for workers to buckle the belt behind themselves (see Figure 2)

- monitor use with in-cab cameras or check vehicle or mobile Heavy Equipment use data.

Engage with your workers about seat belt use

Talk to your workers about the importance

of wearing seat belts at all times. For example:

- provide training on how to wear seat belts correctly. This includes:

- how to alter the adjustable parts of their seat and seat belt to improve comfort

- how to make sure the seat belt is fitting correctly to provide maximum protection

- refer to the vehicle or mobile Heavy Equipment’s user manual for more information on getting the correct fit

- discuss the importance of seat belt use at your regular health and safety meetings, and toolbox and tailgate talks

- consult with your workers and work with them to overcome any issues they may have with wearing seat belts

- provide workers with feedback from seat belt use monitoring data

- share examples of incidents where wearing a seat belt has provided protection, or

- non-wearing has caused harm

- include a seat belt wearing policy in your business health and safety documents and worker training resources.

Focusing on fit and comfort can help overcome any objections to wearing seat belts

Seat belts should fit well and be as comfortable as possible. There are options available for improving seat belt comfort. For example:

- Choose vehicles and mobile Heavy Equipment that have the seat belts integrated with the driver’s seat so the seat belt does not pull against the worker as the vehicle or mobile Heavy Equipment moves (see Figure 3).

- If the vehicle or mobile Heavy Equipment moves in many directions, or works on a slope, use seat belts that provide support and flexibility from multiple angles, such as a 4-point harness (see Figure 4).

- Provide seat belt extenders for workers who cannot comfortably do up the existing seat belt (see Figure 5). Before using a seat belt extender you need to:

- check the weight limit of the extender and the seat. It may be necessary to install a seat with a higher weight rating, which usually includes a larger fitting seat belt as well

- check that the extender is the right one for the make and model of vehicle or mobile Heavy Equipment, or seat belt system. Make sure that it is labelled with the manufacturer’s name and a certification label. Local retailers who sell verified products should be able to provide you with advice.

Seat Belt Safety Campaign , NHTSA Targets Young Males

Consider seat belt options when purchasing or upgrading vehicles or Mobile Heavy Equipment

When purchasing or leasing new vehicles or mobile Heavy Equipment, ask your supplier what seatbelt options are available. Choose vehicles and mobile Heavy Equipment that include the most modern and appropriate seatbelt features for worker comfort and safety. You should also consult with your workers and their representatives about the options available.

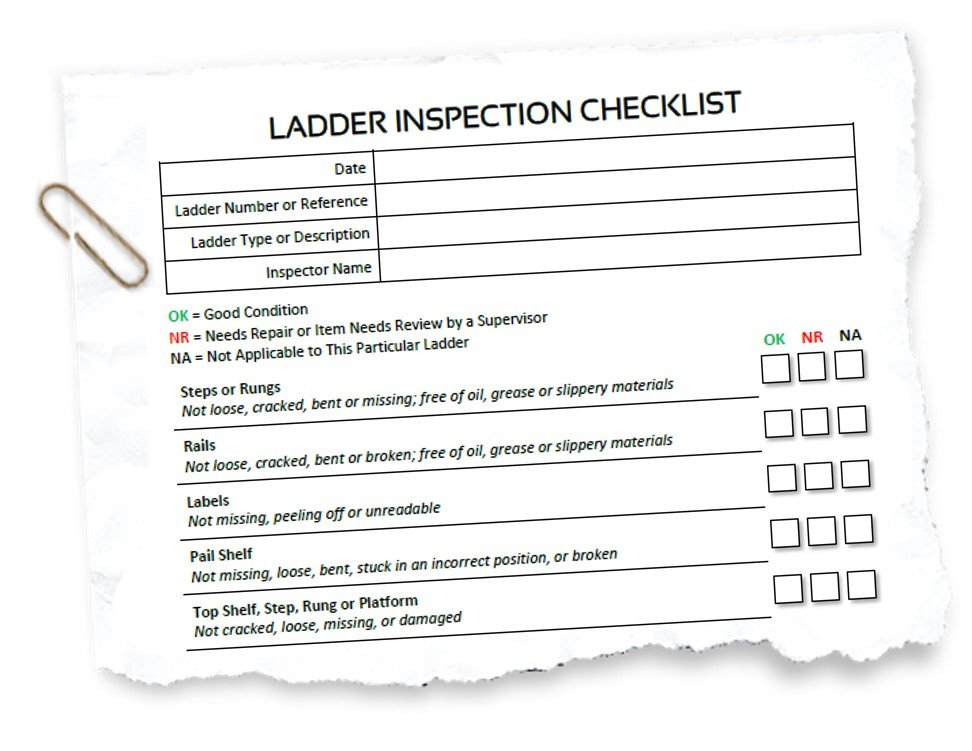

Maintaining seat belts

Make sure seat belts and any approved seat belt modifications are in good working order. Checking the seatbelt should be part of the daily vehicle or mobile Heavy Equipmentsafety check. If a seat belt is showing signs of wear or not functioning properly, it may need replacing. Things to watch out for include:

- seatbelts that don’t buckle up

- signs of wear on the seatbelt – such as torn or fraying seatbelt edges (see Figures 6 and 7)

- a retractable seatbelt that isn’t fully retracting or is locked

- damaged, rusty, or worn anchor points

- missing seatbelts (these should be replaced).

(Site Equipment and Tools Inspection Procedure)

Conclusion

Wearing a seatbelt reduces the chances of workers being injured in-vehicle and mobile Heavy Equipment accidents. we recommend employers make sure workers wear seat belts when using vehicles or mobile Heavy Equipment for work.

As an Employer, you have a duty to make sure, so far as is reasonably practicable, that your workers’ health and safety are not put at risk while carrying out work. This includes when they are using vehicles and mobile Heavy Equipment for work purposes. All vehicle and mobile Heavy Equipment safety features should be used, this includes seatbelts. Seatbelts should not be removed from vehicles or mobile Heavy Equipment.

You must also make sure, so far as is reasonably practicable, that other people at your workplace are not put at risk from your work, such as visitors riding in vehicles.

What are some of the guidelines around using back support belts in the workplace?