A chemical risk assessment involves the identification of chemical hazards in the workplace and recommends controls to reduce exposure and minimize harm to workers. It assesses the transport, storage, and handling of hazardous substances so pre-emptive action can be taken to reduce harm. The identification of hazards, the evaluation of their risks, and the putting in place of control measures to secure the health and safety of employees is a major element for managing health and safety under the Safety, Health and Welfare at Work Act, 2005.

The Chemical Agent Regulations 2001 and 2015 point out the specific requirements necessary to complete a Chemical Agents risk assessment of the chemical agents used in the workplace. A generic assessment is unlikely to meet the requirements of the legislation.

Benefits of Performing Chemical Risk Assessment

For organizations involved in using chemicals in their facilities and everyday operations, it is vital to perform chemical risk assessments. Doing so provides organizations the opportunity to be proactive instead of reactive in handling chemical hazards. Discovering potential risks and hazards allows organizations to set up a health and safety plan to prevent causing harm to employees and damages to company property or equipment.

Types of Chemical Hazards

Chemical hazards can vary depending on what kind of harm or damage they can cause and the way they can cause them. Knowing its types can help in building an effective health and safety plan. Below are 6 types of chemical hazards that industries may encounter:

- Flammable Liquids – One of the most common hazardous chemicals. Flammable liquids are those that easily burn or ignite. Examples: gasoline, acetone, toluene, diethyl ether, diesel fuel, etc.

- Corrosives – These are materials that can cause visible destruction at their point of contact with body tissues or even other materials such as metal. Examples: sulfuric acid, hydrochloric acid, acetic acid, sodium hydroxide, etc.

- Reactive Chemicals – This refers to chemicals liable to explode or react violently upon contact with other substances or upon exposure to external factors such as heat and toxic gases. Examples: benzoyl peroxide, hydrogen peroxide solutions, nitric acid, etc.

- Toxic – These refer to chemicals or substances that cause harm if inhaled, ingested, or absorbed through the skin. Examples: carcinogens, mutagens, poisons, mercury, etc.

- Irritant – Substances that cause harm by irritation, inflammation, or another discomfort to the body. Examples: chlorine, lye, asbestos, etc.

- Environmental Hazard – These are materials containing toxic chemicals that can cause harm to the environment at large. Examples: arsenic, asbestos, mercury, oil, lead, etc.

Top 5 Hazards to Spot in a Chemical Risk Assessment

Here are the top 5 hazards that workplace safety officers need to be aware of when conducting a chemical risk assessment and some tips on how to prevent them.

1. Improper storage of chemicals

Improper storage of hazardous chemicals can lead to explosions, fires, burns, and toxic gas releases. Hazardous chemicals must be carefully stored in appropriate containers and locations according to instruction labeling and regulatory requirements.

An August 2018 chemical leak into the Gulf of Mexico was caused by storing 70 gallons of emulsion breaker in a broken tank.

2. Incorrect labeling of containers

Incorrect labeling of containers can also cause explosions, acid burns, and the release of toxic fumes. According to OSHA, all chemical labels should have pictograms, a signal word, hazard, and precautionary statements, the product identifier, and supplier identification.

( learn more Your-steps-to-chemical-safety/

A UC Berkeley researcher experienced acid burns after pouring isopropanol into a container for unwanted or excess chemicals labeled “isopropanol.” It was later discovered that the container had been holding concentrated nitric acid which caused an explosive acid spray.

3. Prolonged exposure to toxic chemicals

Long-term exposure to hazardous chemicals can lead to the development of illnesses and some types of cancer. Employers should take the initiative to limit or eliminate their employee’s exposure to toxic chemicals by implementing process changes if possible, and providing protective gear

A nuclear facility worker developed serious lung issues due to being exposed to chemical radiation for over 20 years.

4. Lack of proper training to handle chemicals

The lack of training for workers can lead to chemical injuries. Adequate training must be provided to workers who handle or work around hazardous substances to minimize the risk of injury or illness.

A study by the National Institute for Occupational Safety and Health (NIOSH) discovered that more than 12,000 health care workers were often untrained on the hazards of surgical smoke, which can cause both acute and chronic health problems.

5. Poorly maintained equipment

Poorly maintained equipment can malfunction and mishandle chemical substances, or cause flammable chemicals to ignite. Regular equipment maintenance by qualified persons will help reduce the risk of malfunctions.

What steps are involved in the assessment of risk related to chemicals?

A chemical risk assessment should consist of the following steps:

The Risk Assessment Steps

- Identify the chemical hazards associated with the activity e.g. cleaning.

- Consider who might be affected and how they might be harmed.

- Evaluate the risks – what are you doing now and what further precautions are needed?

- Document and implement your findings.

- Update and review as required.

Step 1

The first step in risk assessment is to identify the chemical hazards, associated with the activity. A chemical inventory can be useful. When recording all potential chemical hazards, look beyond the obvious. As well as considering the use of chemical agents, look at chemicals or substances that may be produced by a process, for example, welding fumes, respirable crystalline silica, etc.. Evaluate the internal transport, storage, and quantities of chemicals being stored as well as waste disposal and emergencies e.g. spill or leak. Consider all materials and mixtures, for example, items like glues, foodstuffs, cosmetics, materials used by maintenance such as oils, gardening materials, water treatment, and cleaning materials. It may be possible to group chemicals into specific tasks e.g. cleaning a bathroom and complete a task or activity-based chemical risk assessment.

Check to see whether any of your chemicals are subjected to any Restrictions or Authorisations under the REACH regulation. Again, a chemical inventory can be useful here. Your chemical supplier can supply you with this information and must supply you with a safety data sheet, (SDS) which should be provided with each hazardous material. The SDS is a primary source of health and safety information. For example, the SDS may have your use included in the attached exposure scenarios (ES). It will include occupational exposure limits where they exist or it may have derived no-effect levels (DNELs). (See SDS information)

Step 2

The second step is to consider who (groups of employees) might be affected and how the material/chemical might harm them. Recognize that some employees may need special consideration, for example, language needs of non-national workers, potential exposure of pregnant employees, etc. The different routes of exposure need to be considered e.g. dermal exposure, absorption, inhalation, ingestion, and injection. While the employer is responsible for carrying out the risk assessment, employees should be involved.

Step 3

The third step is evaluating the risks and deciding on precautions. Write down what precautions you are already taking and apply the principles below in the following order to determine what additional precautions are required:

- Eliminate the substance or substitute less hazardous chemicals

- Prevent exposure, for example, by containment and use of local exhaust ventilation (Engineering controls)

- Organize work to reduce the number of employees that might be exposed. Challenge how processes are carried out. Are there smarter ways of carrying out an activity so that the potential for exposure is eliminated or reduced?

- Select, provide training and issue personal protective equipment (this may be required immediately)

- Provide welfare facilities (first-aid and washing facilities to remove contamination)

Step 4

The fourth step is to document and implement your findings. Write down your findings (this can be part of work instructions) and discuss them with your employees. Consultation with your employees is necessary at every step and especially when implementing the findings of your chemicals risk assessment. Be specific with precautions such as PPE e.g. “wear half face mask with A2P2 filter”. You may need to draw up an action plan, detailing who is responsible, for what action, and when will it be carried out.

Step 5

As no workplace remains the same, the fifth step is to review your risk assessment at least once per year and update if necessary. When changes such as new employees, machinery, equipment, or materials occur in the workplace it is necessary to review the risk assessment. Changes in work patterns such as overtime or shift work, the needs of pregnant/nursing employees, and those with special needs must also be included.

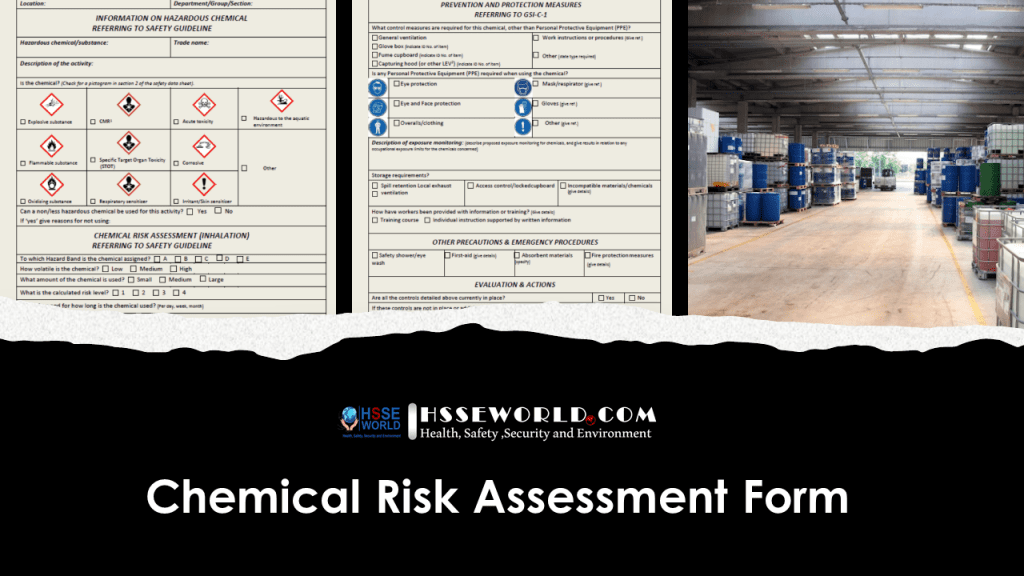

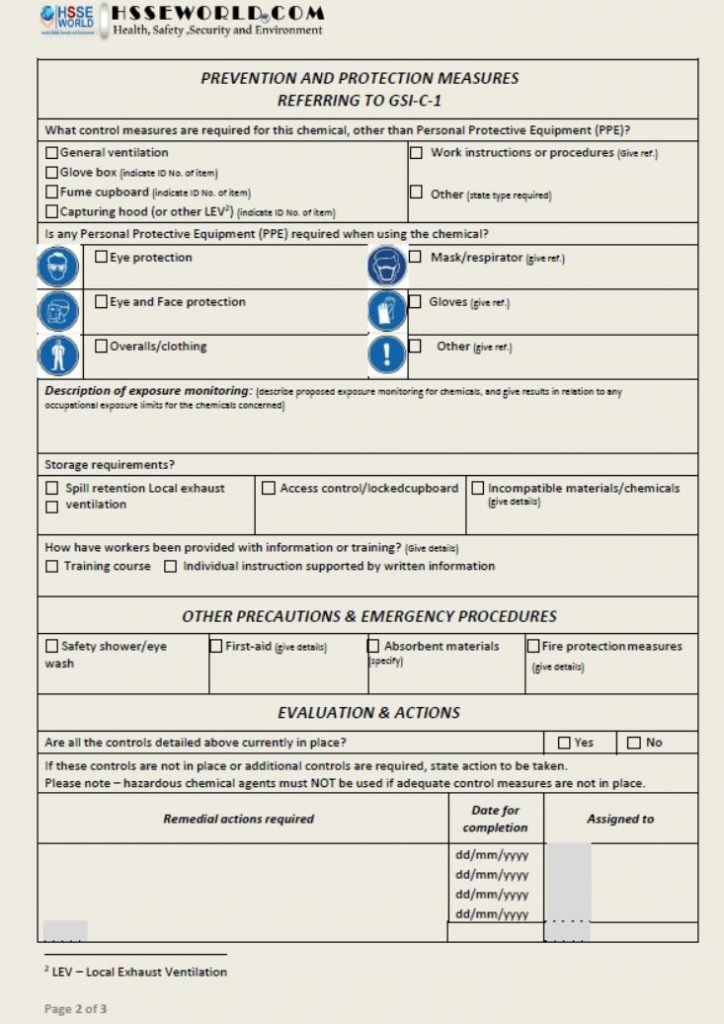

What is a Chemical Risk Assessment Form?

A chemical risk assessment form is used by a safety officer to determine and assess potential chemical hazards and risks associated with tasks that involve the use of hazardous substances in the workplace. This template also helps record and document safety protocols and measures to minimize exposure and harm to workers.

Snapshot of Form

These checklists are not all inclusive. You may wish to add to them or delete portions that do not apply to your workplace. Carefully consider each item as you come to it and then make your decision. Do not spend time with items that have no application to your workplace.

Now you can download the PDF and editable Form and use it to fit your purpose just click on download below

Download the Checklists

Chemical Risk Assessment form PDF

Chemical Risk Assessment form Doc