Anyone who operates, cleans, services, adjusts, and repairs machinery or equipment should be aware of the hazards associated with that machinery. Any powered machinery or electrical equipment that can move in a way that would put people in danger is a hazard that can be prevented by following Lockout and Tagout procedures. Failure to lockout or tag power sources on equipment can result in electrocutions, amputations, and other serious-sometimes fatal accidents.

In this Tool Box Talk, you will be familiar with the Lockout and Tagout procedure in addition to ways of controlling hazard energy at the workplace. the tool box could be downloaded and conducted to all your workers

(Read More: Maintaining your safety for maintenance workers )

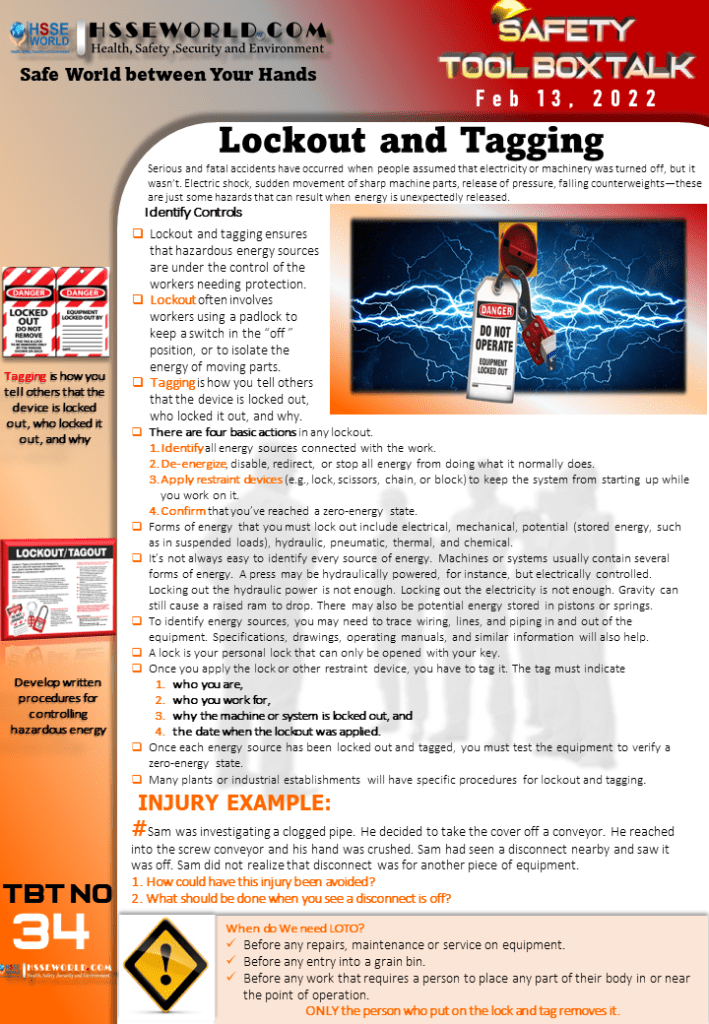

Serious and fatal accidents have occurred when people assumed that electricity or machinery was turned off, but it wasn’t. Electric shock, sudden movement of sharp machine parts, the release of pressure, falling counterweights—these are just some hazards that can result when energy is unexpectedly released.

Identify Controls

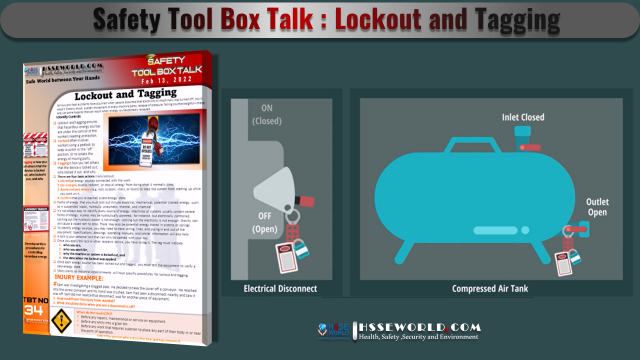

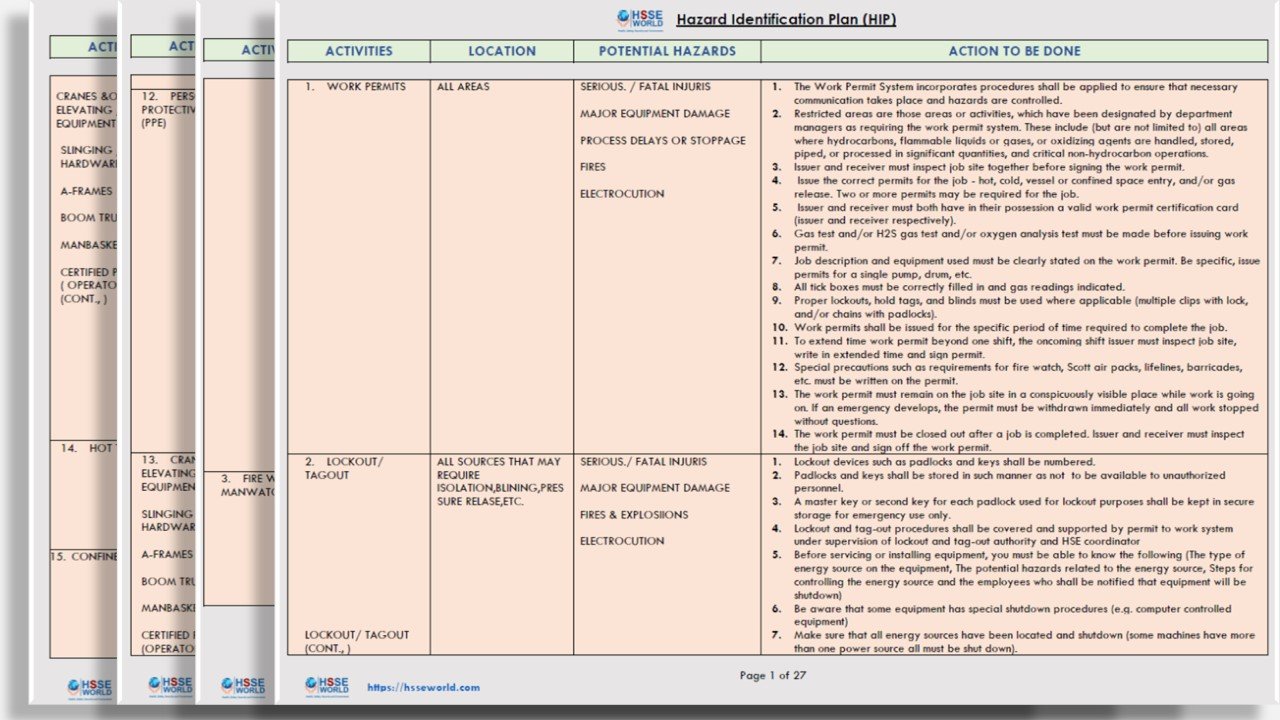

- Lockout and tagging ensures that hazardous energy sources are under the control of the workers needing protection. qLockout often involves workers using a padlock to keep a switch in the “off ” position, or to isolate the energy of moving parts.

- Tagging is how you tell others that the device is locked out, who locked it out, and why.

- There are four basic actions in any lockout.

- Identify all energy sources connected with the work.

- De-energize, disable, redirect, or stop all energy from doing what it normally does.

- .Apply restraint devices (e.g., lock, scissors, chain, or block) to keep the system from starting up while you work on it.

- Confirm that you’ve reached a zero-energy state.( Read more Procedures of Lockout/Tagout at Chemical Plants )

- Forms of energy that you must lock out include electrical, mechanical, potential (stored energy, such as in suspended loads), hydraulic, pneumatic, thermal, and chemical.

- It’s not always easy to identify every source of energy. Machines or systems usually contain several forms of energy. A press may be hydraulically powered, for instance, but electrically controlled. Locking out the hydraulic power is not enough. Locking out the electricity is not enough. Gravity can still cause a raised ram to drop. There may also be potential energy stored in pistons or springs.

- To identify energy sources, you may need to trace wiring, lines, and piping in and out of the equipment. Specifications, drawings, operating manuals, and similar information will also help.

- A lock is your personal lock that can only be opened with your key.

- Once you apply the lock or other restraint device, you have to tag it. The tag must indicate

- who you are,

- who you work for,

- why the machine or system is locked out, and

- the date when the lockout was applied.

- Once each energy source has been locked out and tagged, you must test the equipment to verify a zero-energy state.

- Many plants or industrial establishments will have specific procedures for lockout and tagging.

Download Lock Removal Form

INJURY EXAMPLE:

Sam was investigating a clogged pipe. He decided to take the cover off a conveyor. He reached into the screw conveyor and his hand was crushed. Sam had seen a disconnect nearby and saw it was off. Sam did not realize that disconnect was for another piece of equipment.

- How could have this injury been avoided?

- What should be done when you see a disconnect is off?

Video: Lockout – Tagout Safety Training

When do We need LOTO?

- Before any repairs, maintenance or service on equipment.

- Before any entry into a grain bin.

- Before any work that requires a person to place any part of their body in or near the point of operation.

ONLY the person who put on the lock and tag removes it

Download

E-Books: Safety The Safety Professionals Expanded Guide to LOCKOUT TAGOUTtab)

One thought on “Tool Box Talk: Lockout and Tagging”