We’ve prepared these print-ready posters that communicate important fall protection information using engaging and informative graphics. You may freely download and print these posters to display them in your workplace or break room.

Fall protectin

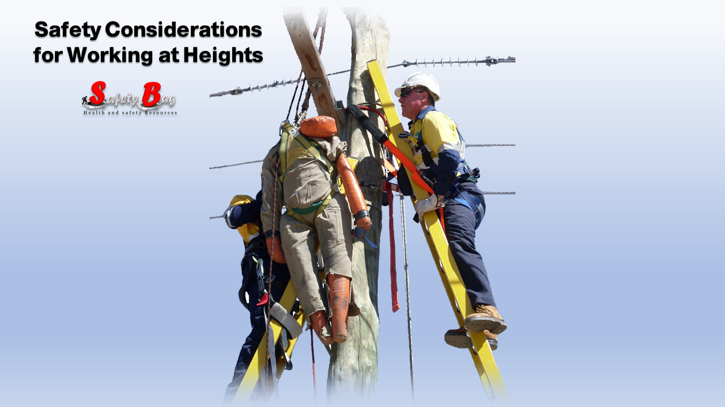

Falls from elevated heights is the most likely type of incident to result in a fatality. A full body safety harness with the “D” ring in the middle of the back is required when there is a fall exposure of six feet or more. All employees shall receive training in accordance with the Fall Protection standard utilizing any fall protection system.

You Can Read the 30-Fall Protection safety poster by flipping the file below

All fall protection devices shall be inspected quarterly by a competent person and marked the proper color coded tape on the “D” ring and lanyard. it’s required to use of shock absorbing lanyards with double-action safety hooks. your oompany shall adopt the plant’s requirement for fall protection if it exceeds it’s requirements. Employees will inspect fall protection equipment before and after each use for the following:

- Belts and straps must be free of frays, broken fibers, damaged stitches, cuts, burns, or chemical damage

- Check the “D” ring and wear pad for distortion, cracks, breaks, and rough or sharp edges

- Inspect buckles and rivets for loose or damaged parts

- Inspect the webbing joints to ensure they are not loose

- Inspect the hooks for distortion, cracks, corrosion, and pitted surfaces

- Ensure the latch seats and locks without binding and should be not distorted or cracked

- Swelling, discoloration, cracks, and charring are obvious signs of chemical or heat damage

- Closely inspect the area where the webbing and the hooks attach for sharp edges and fraying

Also, Read how to inspect Fall Protection Equipment

Why is fall protection important?

Falls are among the most common causes of serious work related injuries and deaths. Employers must set up the work place to prevent employees from falling off of overhead platforms, elevated work stations or into holes in the floor and walls.

Also rea: Books: OSHA Fall Protection Toolbox Talks and Trainer Guide

What can be done to reduce falls?

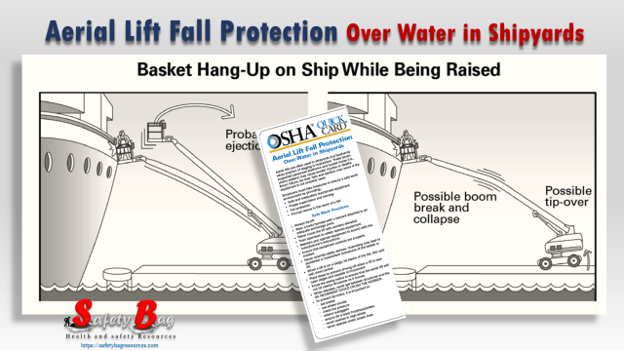

Employers must set up the work place to prevent employees from falling off of overhead platforms, elevated work stations or into holes in the floor and walls. OSHA requires that fall protection be provided at elevations of four feet in general industry workplaces, five feet in shipyards, six feet in the construction industry and eight feet in longshoring operations. In addition, OSHA requires that fall protection be provided when working over dangerous equipment and machinery, regardless of the fall distance.

To prevent employees from being injured from falls, employers must:

- Guard every floor hole into which a worker can accidentally walk (using a railing and toe-board or a floor hole cover).

- Provide a guard rail and toe-board around every elevated open sided platform, floor or runway.

- Regardless of height, if a worker can fall into or onto dangerous machines or equipment (such as a vat of acid or a conveyor belt) employers must provide guardrails and toe-boards to prevent workers from falling and getting injured.

- Other means of fall protection that may be required on certain jobs include safety harness and line, safety nets, stair railings and hand rails.

OSHA requires employers to:

- Provide working conditions that are free of known dangers.

- Keep floors in work areas in a clean and, so far as possible, a dry condition.

- Select and provide required personal protective equipment at no cost to workers.

- Train workers about job hazards in a language that they can understand.

Download the Posters

30-Fall Protection’s Posters

Also Read: Books: OSHA-Permit Required Confined Spaces